Production flow of cast acrylic sheet

In the plastic field, acrylic is a thermoplastic engineering plastic with excellent comprehensive properties, mostly used in the form of panels for outdoor and indoor signboards. In the application industry, its materials are generally in the form of particles, plates, tubes, etc., cast acrylic sheets according to the production process of separate casting plate and extrusion plate.

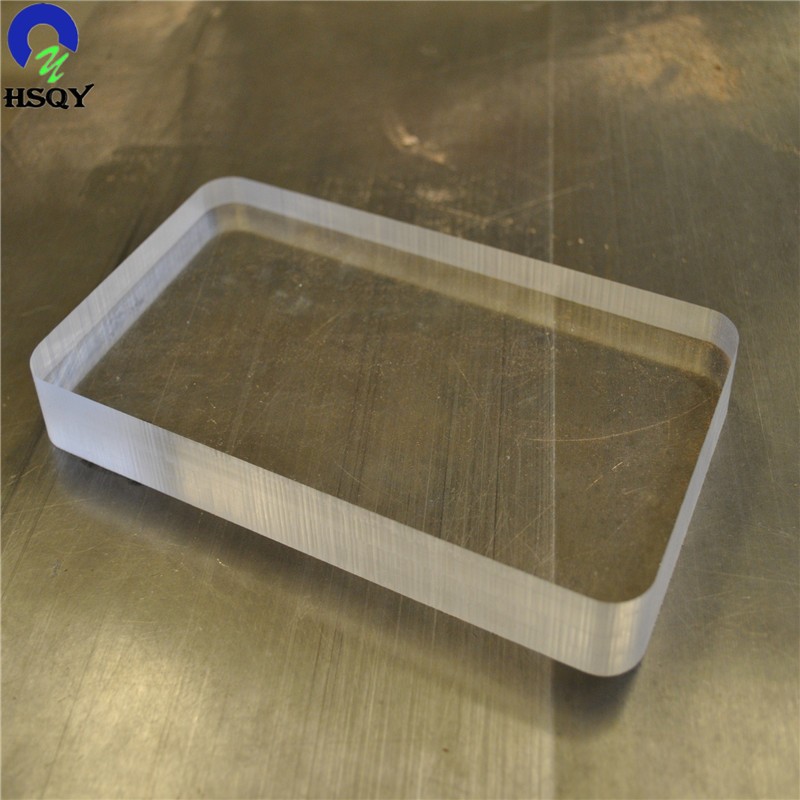

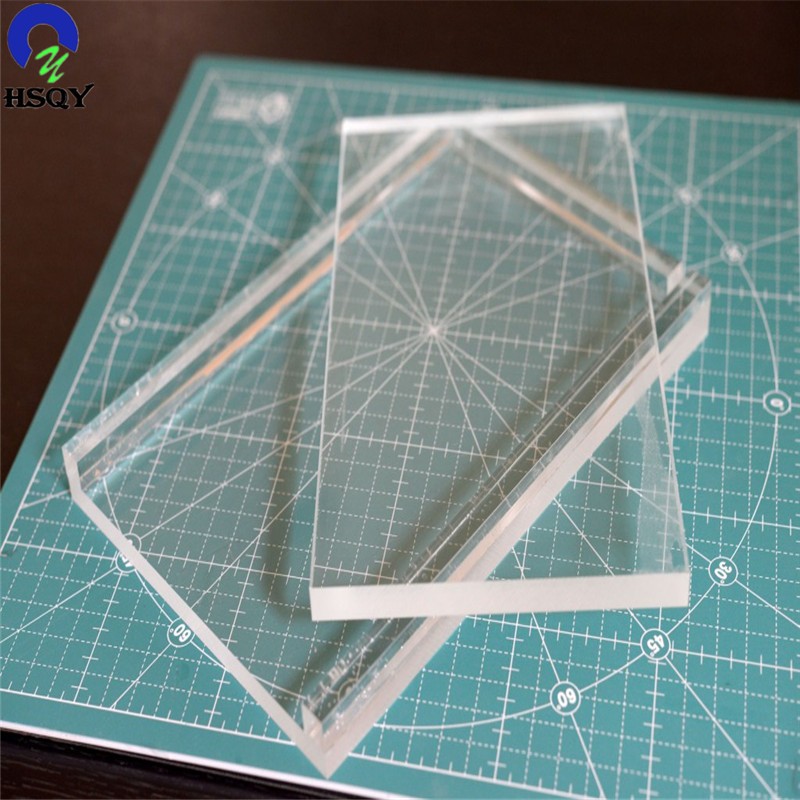

Extruded plate: compared with cast plate, the extruded plate has a lower molecular weight, weaker mechanical properties, and higher flexibility. However, this feature is conducive to bending and hot forming processing, softening time is shorter. Dealing with the larger size of the plate is conducive to a variety of rapid vacuum plastic molding. At the same time, the thickness tolerance of extruded plate is smaller than that of the cast plate. As extrusion plate is a large number of automated production, color and specifications are inconvenient to adjust, so product specification diversity is subject to certain restrictions.Cast plate: high molecular weight, excellent stiffness, strength, and excellent chemical resistance. Therefore, it is suitable for large-size cast acrylic sheets, which take a little longer time in the softening process. This kind of sheet is characterized by small batch processing, incomparable flexibility in the color system and surface texture effects, and complete product specifications, practical for a variety of special purposes.

HSQY is a professional PET sheet factory, we specialize in providing you with high-quality cast acrylic sheets and related accessories. We support a global fast delivery service for your order. If you have any questions, please e-mail us at: vivi@hgqyplastic.com.

vivi@hgqyplastic.com

vivi@hgqyplastic.com