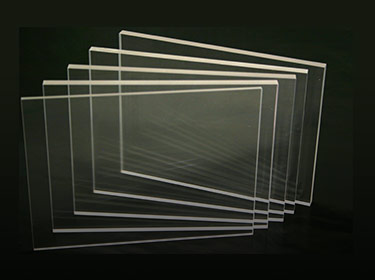

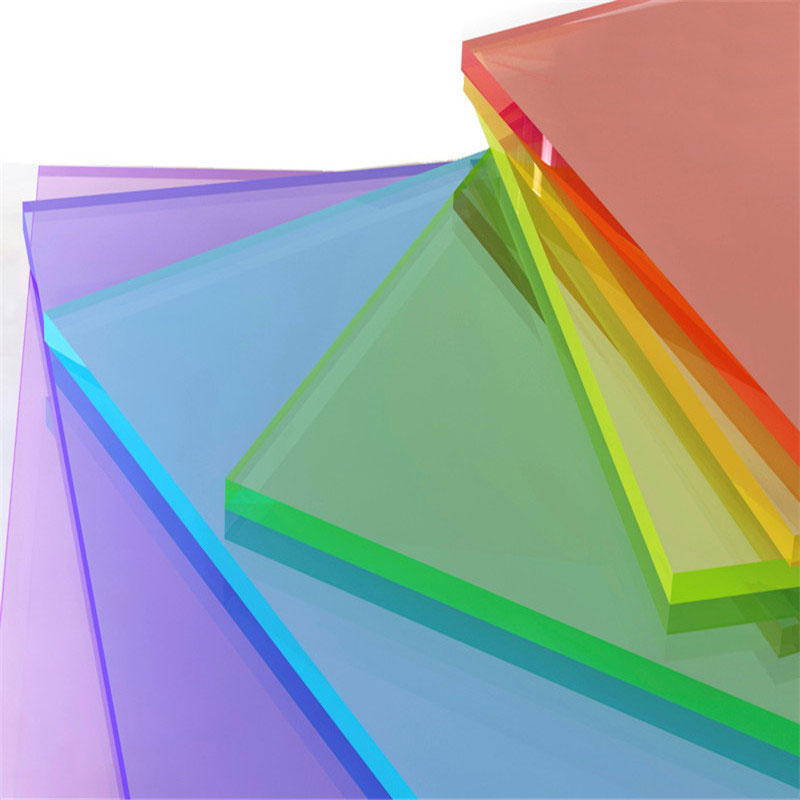

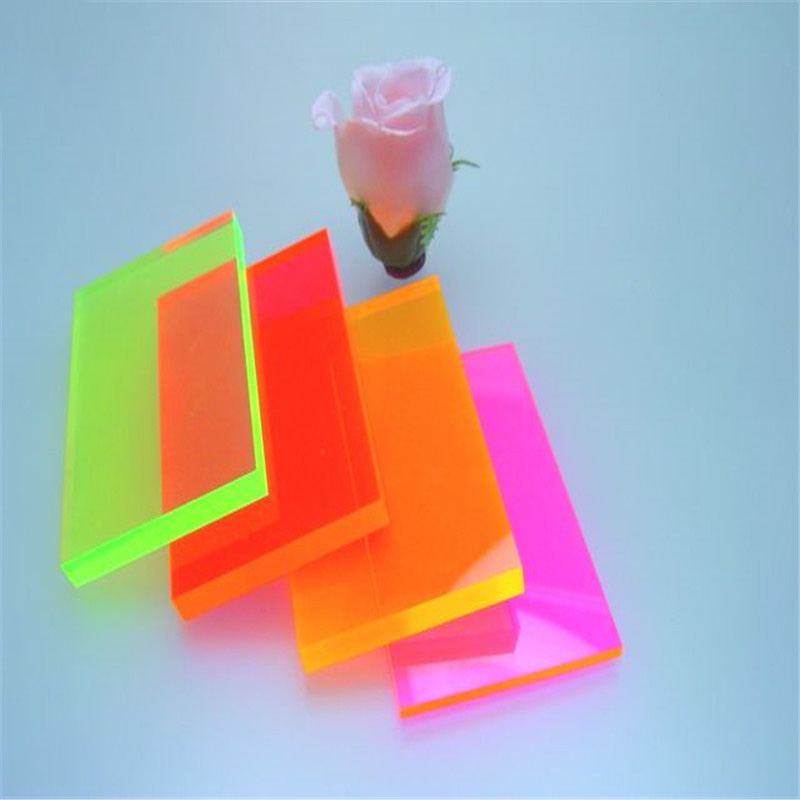

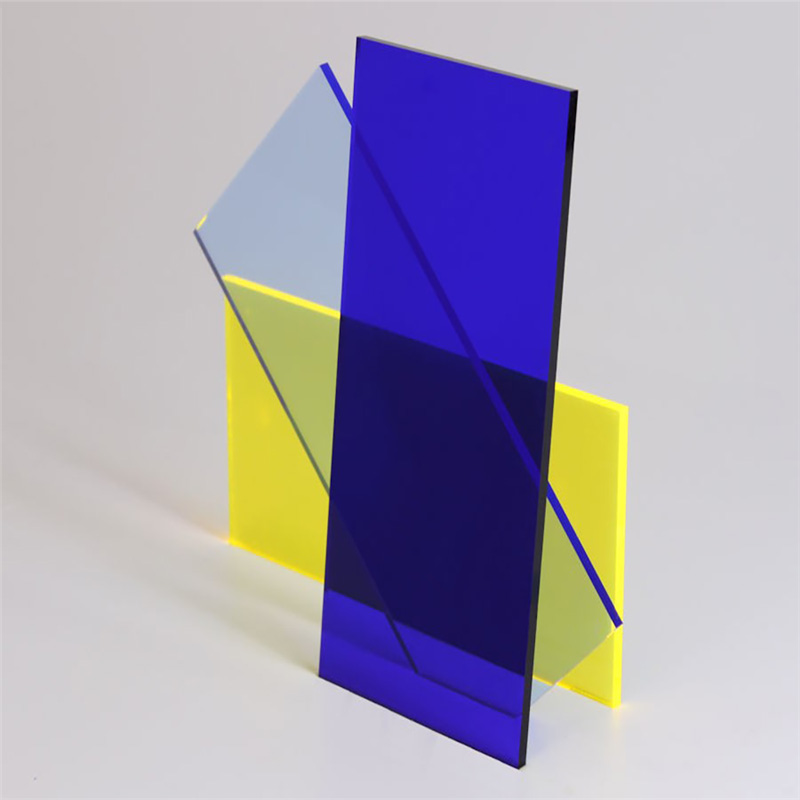

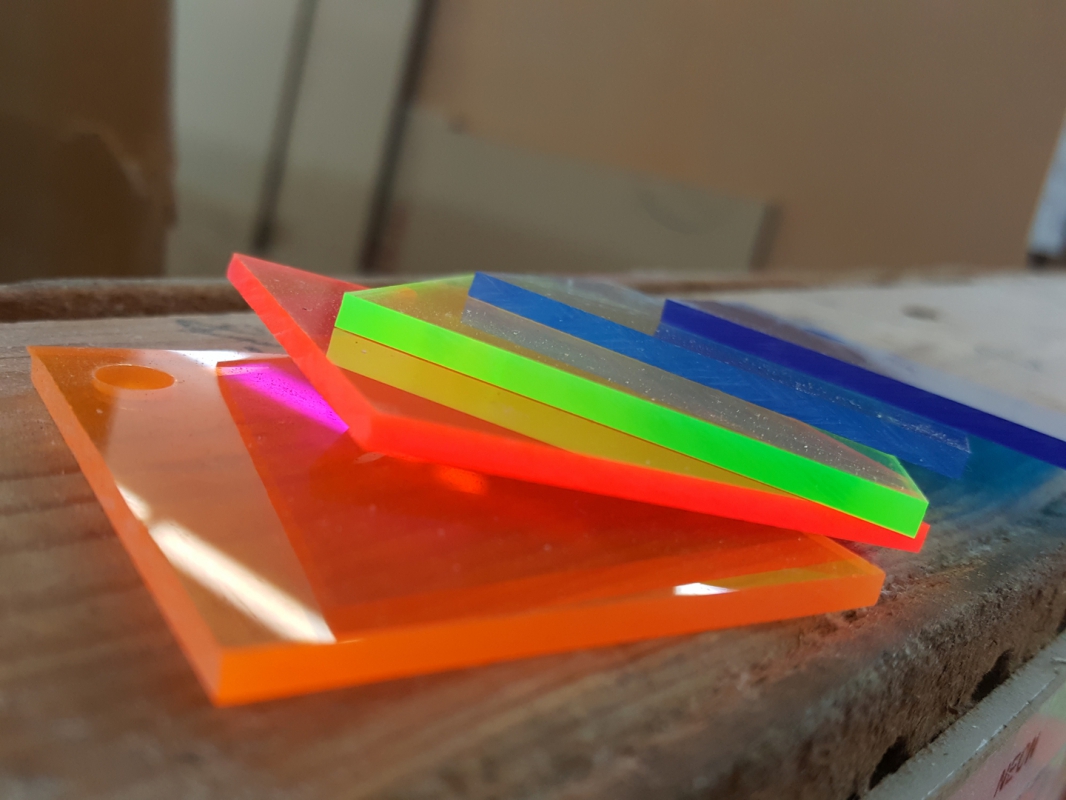

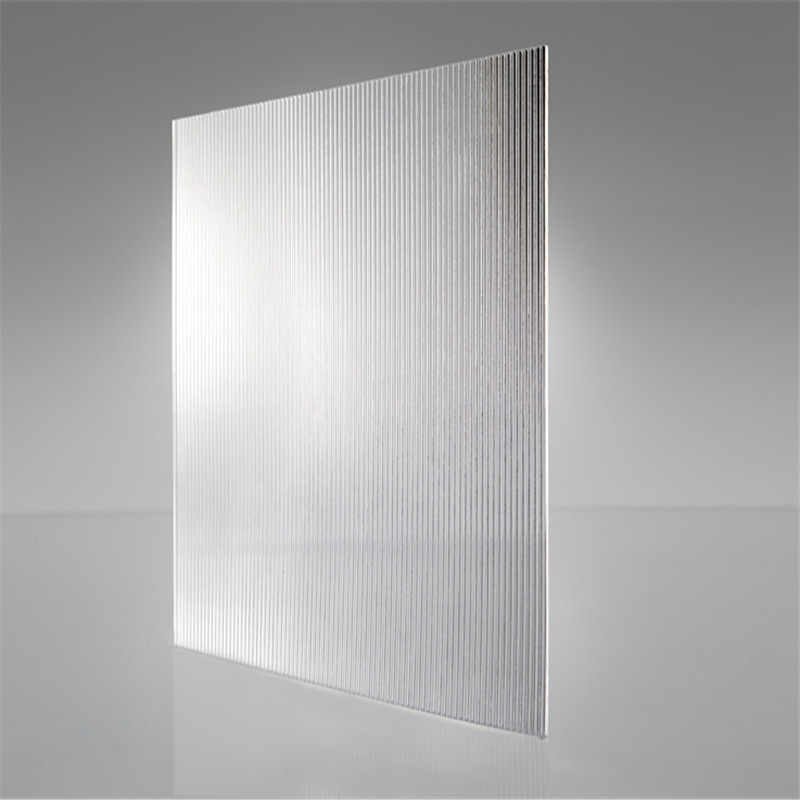

Acrylic is another common plastic around our daily life. Because of its high transparency, it has another name, plexiglass. Acrylic sheet has crystal-like transparency, and its light transmittance is more than 92%. colored acrylic sheet with dyes has a good color performance.

In addition, acrylic sheet has excellent weather resistance, high surface hardness and surface gloss and good high temperature resistance.

According to the production flow, acrylic sheets can be divided into extruded acrylic sheets and cast acrylic sheets.Both extruded acrylic and cast acrylic sheets have their own advantages and disadvantages. According to different usage scenarios, we can choose different acrylic sheets.

ACRYLIC SHEET

01

Excellent processing performance

02

High gloss&smooth surface

03

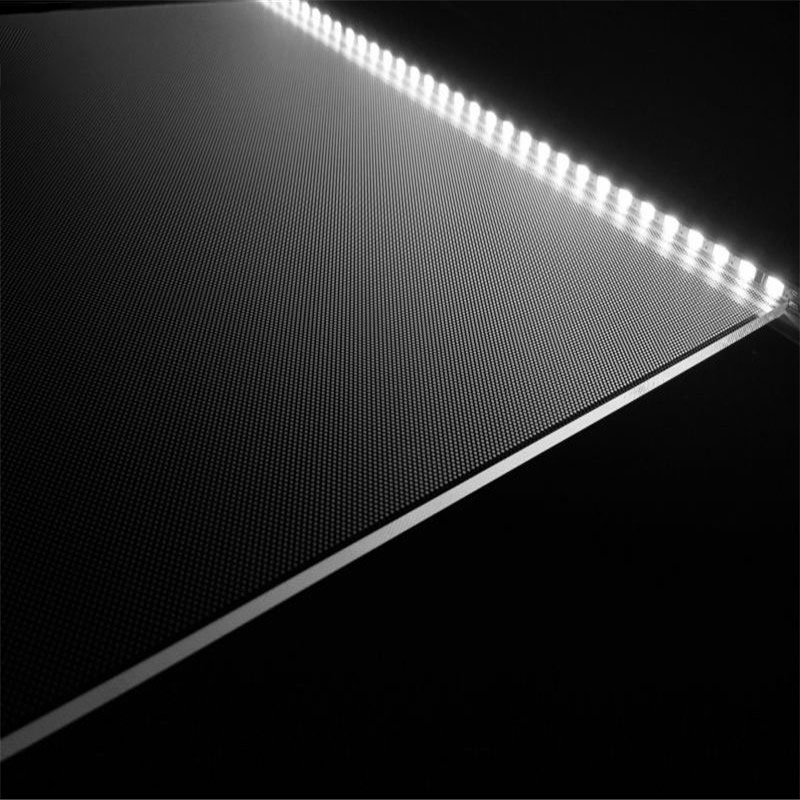

93% light transmittance

04

Good chemical resistance.

POPULAR PRODUCTS

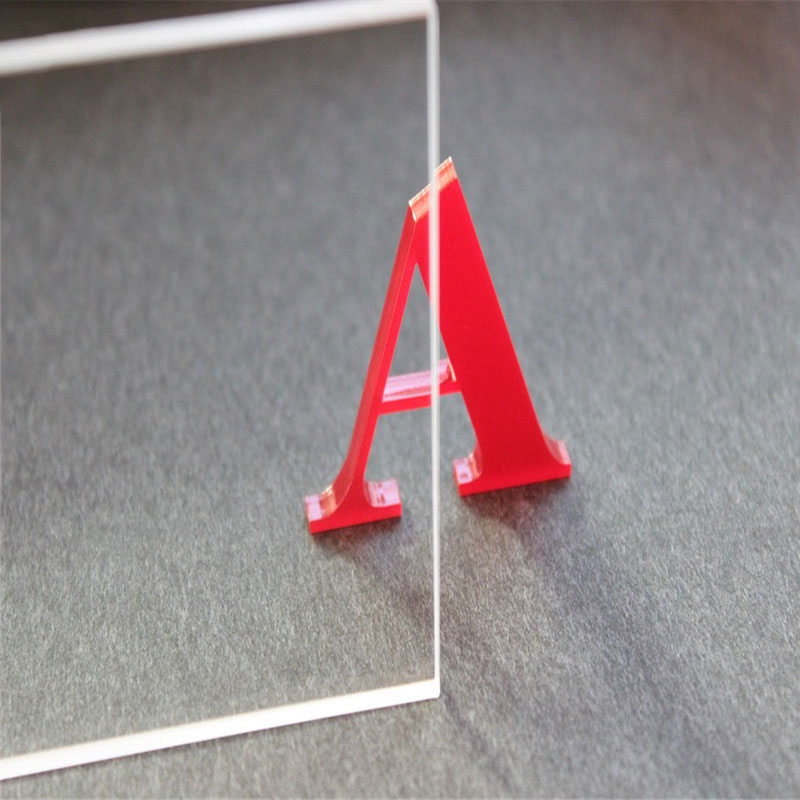

Clear Color Acrylic Sheet

OUR FACTORY

HSQY plastic group is the leading acrylic manufacturer &supplier in China,we have more than 20 years export experience,there are professional team can provide tech support and goods customer service.

There are 4 acrylic extrude lines and 4 acrylic cast lines in factory , our daily capacity is more than 100 tons per day.

As a leading cast &extrude acrylic supplier,HSQY plastic group can provide many different kinds of acrylic sheet,such as clear acrylic sheet;black acrylic sheet;4*8 acrylic sheet;iridescent acrylic sheet;red acrylic sheet;blue acrylic sheet;acrylic mirror sheet;anti-scratch acrylic sheet;colored acrylic sheet and so on.

In addition to these conventional products, we also have a professional plastic processing center that can provide a series of plastic processing services, such as cut acrylic sheet to size;customizable size acrylic sheet;printing on acrylic sheet;painting on acrylic sheet.

There are 4 acrylic extrude lines and 4 acrylic cast lines in factory , our daily capacity is more than 100 tons per day.

As a leading cast &extrude acrylic supplier,HSQY plastic group can provide many different kinds of acrylic sheet,such as clear acrylic sheet;black acrylic sheet;4*8 acrylic sheet;iridescent acrylic sheet;red acrylic sheet;blue acrylic sheet;acrylic mirror sheet;anti-scratch acrylic sheet;colored acrylic sheet and so on.

In addition to these conventional products, we also have a professional plastic processing center that can provide a series of plastic processing services, such as cut acrylic sheet to size;customizable size acrylic sheet;printing on acrylic sheet;painting on acrylic sheet.

PRODUCTION STATUS

5-10 DAYS

<10tons

10-15 DAYS

10-20tons

15-20 DAYS

20-50tons

>20 DAYS

>50tons

0

0Shopping Cart

Delete all items

Proceed to send inquiry

PRODUCTS

#FAQ

- What is Acrylic?

- The advantage of acrylic sheet?

- The disadvantage of acrylic sheet?

- How process acrylic sheet?

- What should I pay attention to when using acrylic sheet?

- What is the application of acrylic sheet ?

- What is the different cols of acrylic sheet?

- What size acrylic sheet can you do ?

- What is the thickness of acrylic sheet can you make?

- What is the different types of acrylic sheet?

Acrylic, also known as PMMA or plexiglass, its chemical name is polymethyl methacrylate,there are different types of acrylic sheet,such as extrude acrylic sheet;cast acrylic sheet;acrylic mirror sheet and so on. It is an important plastic polymer material that has been developed long time ago. It’s high transparency, high chemical stability and weather resistance, also easy dyeing, easy processing, and with excellent appearance. It has a wide range of applications in the construction industry.

1. High transparency

Transparent acrylic sheet light transmittance is above 92%

2. Excellent weather resistance

It is highly adaptable to the natural environment. Even if it is exposed to sunlight, wind and rain for a long time, its col will not change.

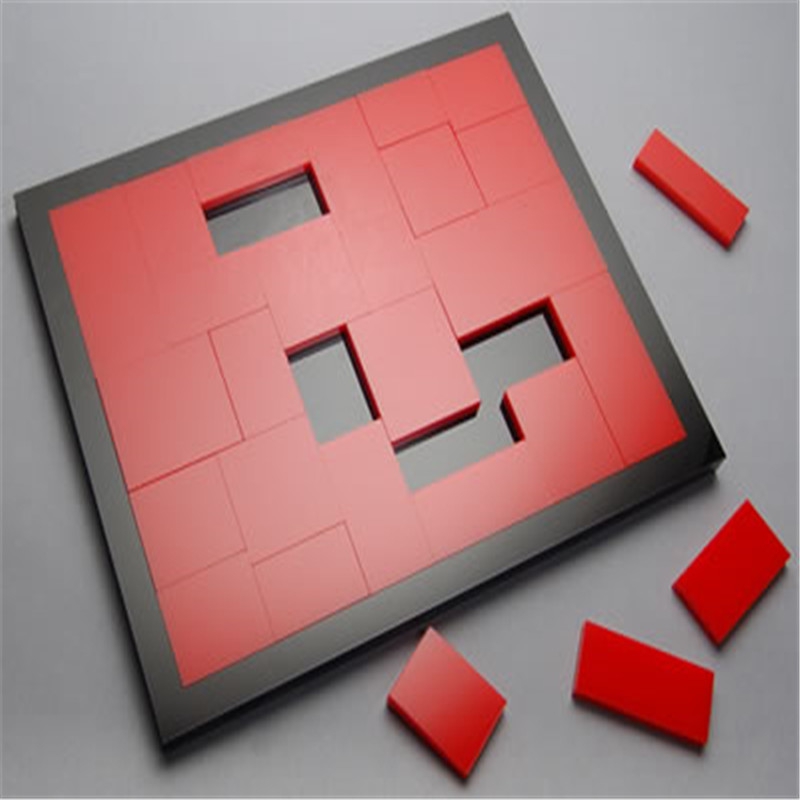

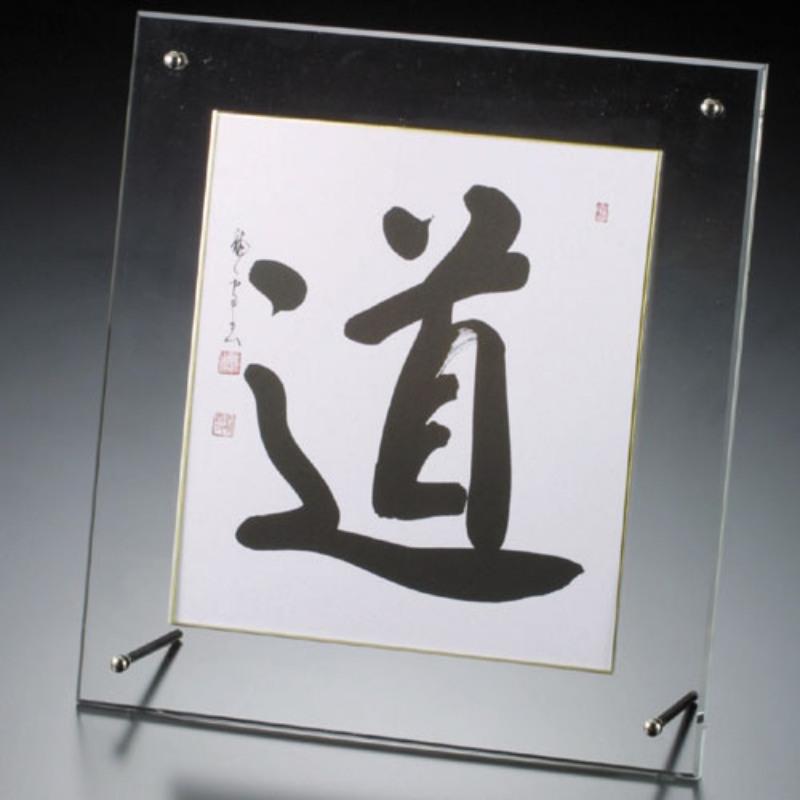

3. Good processing performance

Suitable for cutting and thermoforming,we can use it to make all kinds of crafts, such as acrylic boxes, acrylic display standard,acrylic table sneeze guard,photo frames, display cards, display bases, etc.

3. Excellent comprehensive performance

Acrylic sheets can be dyed into many different cols, and the surface can be painted, silk-screened or vacuum coated

5. Non-toxic, even if it is in long-term contact with skin directly, it is harmless

Transparent acrylic sheet light transmittance is above 92%

2. Excellent weather resistance

It is highly adaptable to the natural environment. Even if it is exposed to sunlight, wind and rain for a long time, its col will not change.

3. Good processing performance

Suitable for cutting and thermoforming,we can use it to make all kinds of crafts, such as acrylic boxes, acrylic display standard,acrylic table sneeze guard,photo frames, display cards, display bases, etc.

3. Excellent comprehensive performance

Acrylic sheets can be dyed into many different cols, and the surface can be painted, silk-screened or vacuum coated

5. Non-toxic, even if it is in long-term contact with skin directly, it is harmless

1. The product has low hardness and the surface is easy to scratch

2. Not resistant to high temperatures

3. The price is much more expensive than ordinary glass

2. Not resistant to high temperatures

3. The price is much more expensive than ordinary glass

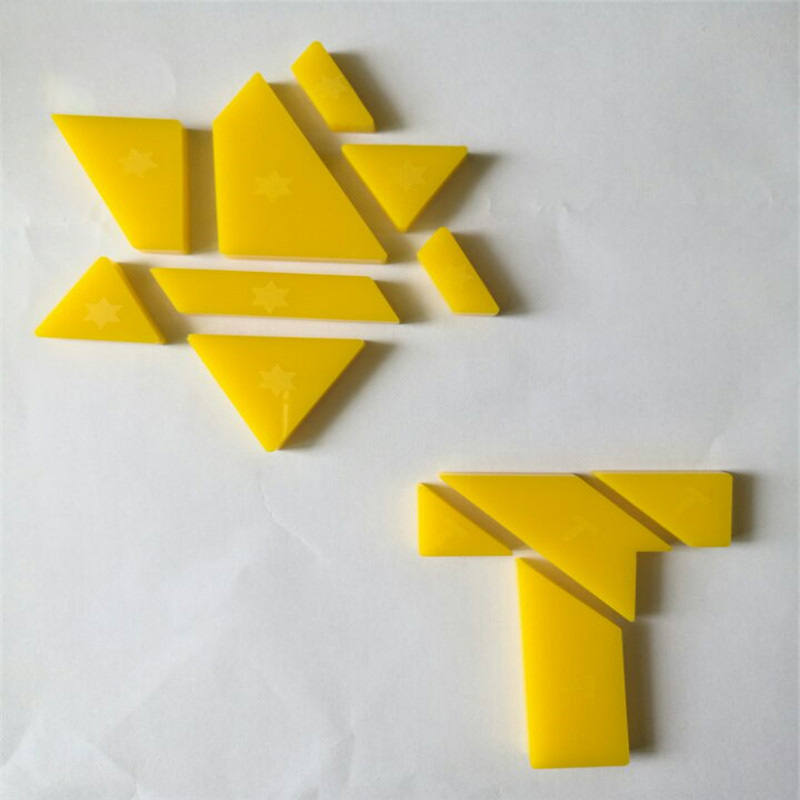

Acrylic sheets have good processing properties, which can be thermoformed (including compression molding, blow molding and vacuum molding), or mechanical processing methods such as drilling, turning, cutting, etc. The mechanical cutting and engraving controlled by a microcomputer not only greatly improves the processing accuracy, but also produces patterns and shapes that cannot be completed by traditional methods. In addition, the acrylic sheet can be laser cut and laser engraved to produce products with peculiar effects. "

1. Acrylic sheet cannot be stored in the same place with other organic solvents, let alone contact with organic solvents.

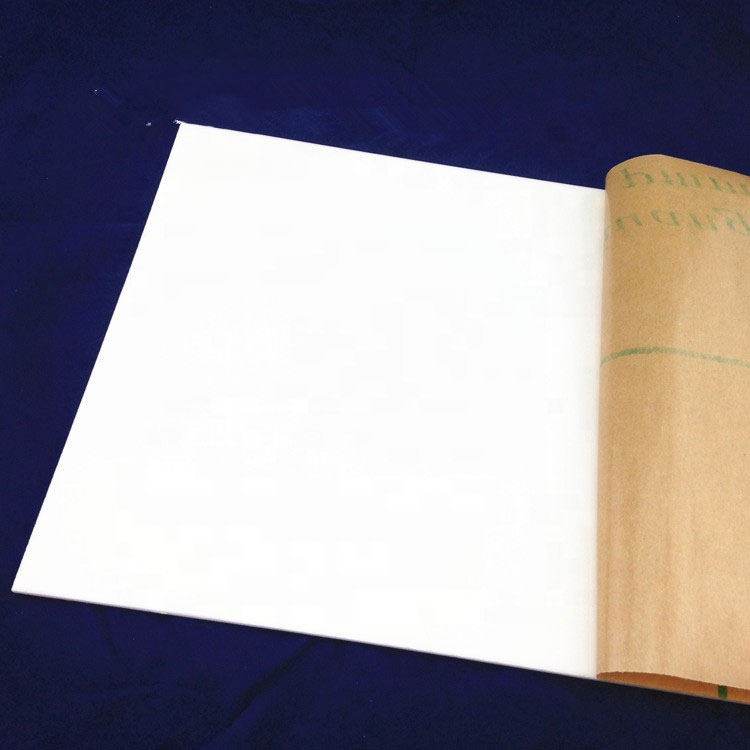

2. During transportation, the surface protective film or protective paper cannot be scratched.

3. It cannot be used in an environment where the temperature exceeds 85°C.

4. When cleaning the acrylic sheet, only 1% soapy water is needed. Use a soft cotton cloth dipped in soapy water. Do not use hard objects or dry wipes, otherwise the surface will be easily scratched.

5. Acrylic plate has a large thermal expansion coefficient, so the expansion gap should be reserved due to temperature changes.

2. During transportation, the surface protective film or protective paper cannot be scratched.

3. It cannot be used in an environment where the temperature exceeds 85°C.

4. When cleaning the acrylic sheet, only 1% soapy water is needed. Use a soft cotton cloth dipped in soapy water. Do not use hard objects or dry wipes, otherwise the surface will be easily scratched.

5. Acrylic plate has a large thermal expansion coefficient, so the expansion gap should be reserved due to temperature changes.

1. Architectural applications: shop windows, soundproof doors and windows, lighting shades, telephone booths, etc.

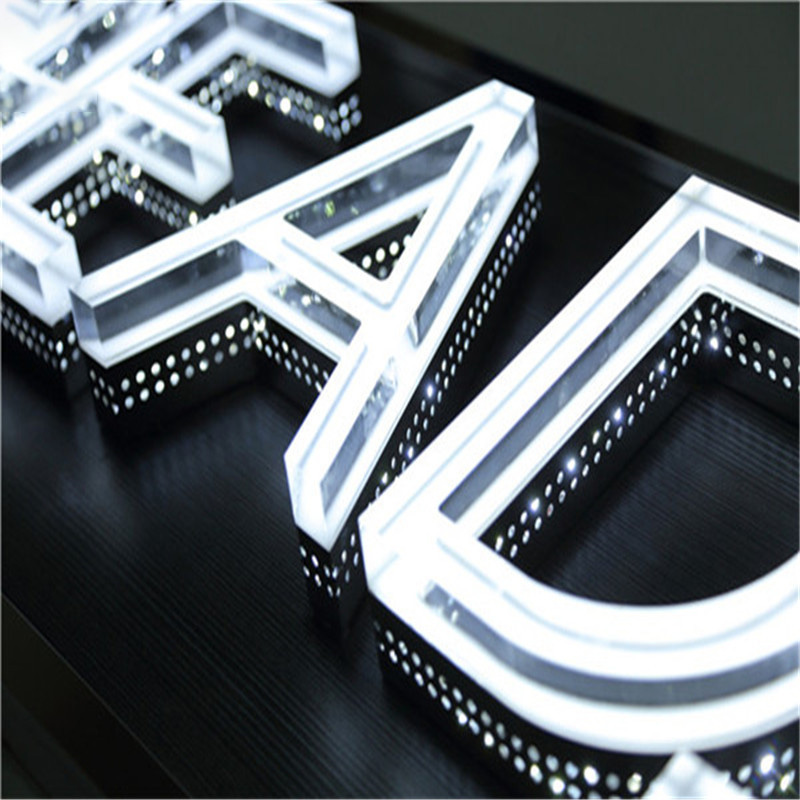

2. Advertising applications: light boxes, signs, signs, display racks, etc.

3. Transportation applications: doors and windows of trains, automobiles and other vehicles.

4. Medical applications: baby incubators, various surgical medical appliances, civilian products: bathroom facilities, handicrafts, cosmetics, brackets, aquariums, etc.

5. Industrial applications: instrument surface panels and protective covers, etc.

6. Lighting applications: fluorescent lamps, chandeliers, street lampshades, etc.

7.Acrylic sheet for fish tank,Acrylic sheet for swimming pool.

2. Advertising applications: light boxes, signs, signs, display racks, etc.

3. Transportation applications: doors and windows of trains, automobiles and other vehicles.

4. Medical applications: baby incubators, various surgical medical appliances, civilian products: bathroom facilities, handicrafts, cosmetics, brackets, aquariums, etc.

5. Industrial applications: instrument surface panels and protective covers, etc.

6. Lighting applications: fluorescent lamps, chandeliers, street lampshades, etc.

7.Acrylic sheet for fish tank,Acrylic sheet for swimming pool.

he acrylic sheet is easy to dye,so there are different cols of acrylic sheet,such as clear acrylic sheet;black acrylic sheet;white acrylic sheet;colourful acrylic sheet;iridescent acrylic sheeet;textured acrylic sheet;colored acrylic sheet;opaque acrylic sheet;translucent acrylic sheet and so on. If you want see our col catalogue,please contact with me,we can provide acrylic col catalogue for free.

We can provide variety size of acrylic sheet,here is the most common size for your reference / 4*8 acrylic sheet / acrylic sheet cut to size / 24 x 36 acrylic sheet / 48 x 96 acrylic sheet

The thickness we can make is from 1mm to 200mm,the below thickness is what we normally make. 1mm acrylic sheet / 2mm acrylic sheet / 1/2 inch acrylic sheet / 1/8 acrylic sheet / 1/4 inch acrylic sheet / 3/8 inch acrylic sheet / 3/16 acrylic sheet / 3mm acrylic sheet

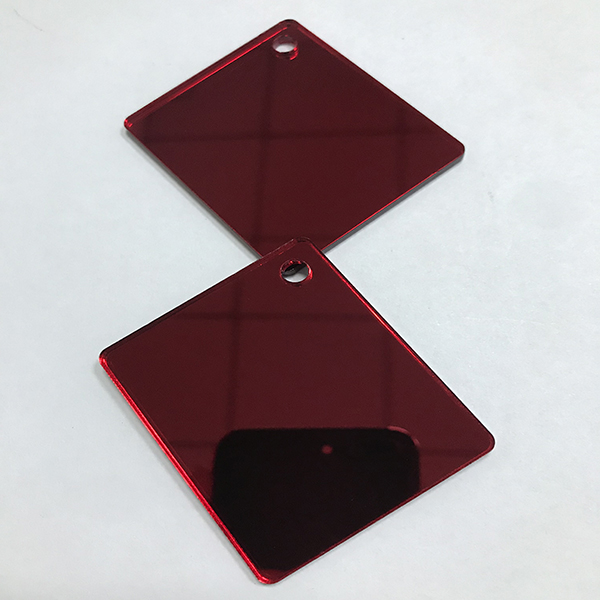

here are different types of acrylic sheets,such as extrude acrylic sheet;cast acrylic sheet;acrylic mirror sheet;acrylic thick sheet;acrylic thin sheet;opaque acrylic sheet;glitter acrylic sheet;two color acrylic sheet.HSQY plastic group is the famous acrylic manufacturer in China,our quality and service are competitive in the market,you are welcome to contact with us.

F&Q

- 1-5

- 6-10

- What is Acrylic?

- Acrylic, also known as PMMA or plexiglass, its chemical name is polymethyl methacrylate,there are different types of acrylic sheet,such as extrude acrylic sheet;cast acrylic sheet;acrylic mirror sheet and so on. It is an important plastic polymer material that has been developed long time ago. It’s high transparency, high chemical stability and weather resistance, also easy dyeing, easy processing, and with excellent appearance. It has a wide range of applications in the construction industry.

- The advantage of acrylic sheet?

- 1. High transparency

Transparent acrylic sheet light transmittance is above 92%

2. Excellent weather resistance

It is highly adaptable to the natural environment. Even if it is exposed to sunlight, wind and rain for a long time, its col will not change.

3. Good processing performance

Suitable for cutting and thermoforming,we can use it to make all kinds of crafts, such as acrylic boxes, acrylic display standard,acrylic table sneeze guard,photo frames, display cards, display bases, etc.

3. Excellent comprehensive performance

Acrylic sheets can be dyed into many different cols, and the surface can be painted, silk-screened or vacuum coated

5. Non-toxic, even if it is in long-term contact with skin directly, it is harmless - The disadvantage of acrylic sheet?

- 1. The product has low hardness and the surface is easy to scratch

2. Not resistant to high temperatures

3. The price is much more expensive than ordinary glass - How process acrylic sheet?

- Acrylic sheets have good processing properties, which can be thermoformed (including compression molding, blow molding and vacuum molding), or mechanical processing methods such as drilling, turning, cutting, etc. The mechanical cutting and engraving controlled by a microcomputer not only greatly improves the processing accuracy, but also produces patterns and shapes that cannot be completed by traditional methods. In addition, the acrylic sheet can be laser cut and laser engraved to produce products with peculiar effects. "

- What should I pay attention to when using acrylic sheet?

- 1. Acrylic sheet cannot be stored in the same place with other organic solvents, let alone contact with organic solvents.

2. During transportation, the surface protective film or protective paper cannot be scratched.

3. It cannot be used in an environment where the temperature exceeds 85°C.

4. When cleaning the acrylic sheet, only 1% soapy water is needed. Use a soft cotton cloth dipped in soapy water. Do not use hard objects or dry wipes, otherwise the surface will be easily scratched.

5. Acrylic plate has a large thermal expansion coefficient, so the expansion gap should be reserved due to temperature changes. - What is the application of acrylic sheet ?

- 1. Architectural applications: shop windows, soundproof doors and windows, lighting shades, telephone booths, etc.

2. Advertising applications: light boxes, signs, signs, display racks, etc.

3. Transportation applications: doors and windows of trains, automobiles and other vehicles.

4. Medical applications: baby incubators, various surgical medical appliances, civilian products: bathroom facilities, handicrafts, cosmetics, brackets, aquariums, etc.

5. Industrial applications: instrument surface panels and protective covers, etc.

6. Lighting applications: fluorescent lamps, chandeliers, street lampshades, etc.

7.Acrylic sheet for fish tank,Acrylic sheet for swimming pool. - What is the different cols of acrylic sheet?

- he acrylic sheet is easy to dye,so there are different cols of acrylic sheet,such as clear acrylic sheet;black acrylic sheet;white acrylic sheet;colourful acrylic sheet;iridescent acrylic sheeet;textured acrylic sheet;colored acrylic sheet;opaque acrylic sheet;translucent acrylic sheet and so on. If you want see our col catalogue,please contact with me,we can provide acrylic col catalogue for free.

- What size acrylic sheet can you do?

- We can provide variety size of acrylic sheet,here is the most common size for your reference / 4*8 acrylic sheet / acrylic sheet cut to size / 24 x 36 acrylic sheet / 48 x 96 acrylic sheet

- What is the thickness of acrylic sheet can you make?

- The thickness we can make is from 1mm to 200mm,the below thickness is what we normally make. 1mm acrylic sheet / 2mm acrylic sheet / 1/2 inch acrylic sheet / 1/8 acrylic sheet / 1/4 inch acrylic sheet / 3/8 inch acrylic sheet / 3/16 acrylic sheet / 3mm acrylic sheet

- What is the different types of acrylic sheet?

- here are different types of acrylic sheets,such as extrude acrylic sheet;cast acrylic sheet;acrylic mirror sheet;acrylic thick sheet;acrylic thin sheet;opaque acrylic sheet;glitter acrylic sheet;two color acrylic sheet.HSQY plastic group is the famous acrylic manufacturer in China,our quality and service are competitive in the market,you are welcome to contact with us.

What is Acrylic?

Acrylic, also known as PMMA or plexiglass, its chemical name is polymethyl methacrylate,there are different types of acrylic sheet,such as extrude acrylic sheet;cast acrylic sheet;acrylic mirror sheet and so on. It is an important plastic polymer material that has been developed long time ago. It’s high transparency, high chemical stability and weather resistance, also easy dyeing, easy processing, and with excellent appearance. It has a wide range of applications in the construction industry.

The advantage of acrylic sheet?

1. High transparency

Transparent acrylic sheet light transmittance is above 92%

2. Excellent weather resistance

It is highly adaptable to the natural environment. Even if it is exposed to sunlight, wind and rain for a long time, its col will not change.

3. Good processing performance

Suitable for cutting and thermoforming,we can use it to make all kinds of crafts, such as acrylic boxes, acrylic display standard,acrylic table sneeze guard,photo frames, display cards, display bases, etc.

3. Excellent comprehensive performance

Acrylic sheets can be dyed into many different cols, and the surface can be painted, silk-screened or vacuum coated

5. Non-toxic, even if it is in long-term contact with skin directly, it is harmless

Transparent acrylic sheet light transmittance is above 92%

2. Excellent weather resistance

It is highly adaptable to the natural environment. Even if it is exposed to sunlight, wind and rain for a long time, its col will not change.

3. Good processing performance

Suitable for cutting and thermoforming,we can use it to make all kinds of crafts, such as acrylic boxes, acrylic display standard,acrylic table sneeze guard,photo frames, display cards, display bases, etc.

3. Excellent comprehensive performance

Acrylic sheets can be dyed into many different cols, and the surface can be painted, silk-screened or vacuum coated

5. Non-toxic, even if it is in long-term contact with skin directly, it is harmless

The disadvantage of acrylic sheet?

1. The product has low hardness and the surface is easy to scratch

2. Not resistant to high temperatures

3. The price is much more expensive than ordinary glass

2. Not resistant to high temperatures

3. The price is much more expensive than ordinary glass

How process acrylic sheet?

Acrylic sheets have good processing properties, which can be thermoformed (including compression molding, blow molding and vacuum molding), or mechanical processing methods such as drilling, turning, cutting, etc. The mechanical cutting and engraving controlled by a microcomputer not only greatly improves the processing accuracy, but also produces patterns and shapes that cannot be completed by traditional methods. In addition, the acrylic sheet can be laser cut and laser engraved to produce products with peculiar effects. "

What should I pay attention to when using acrylic sheet?

1. Acrylic sheet cannot be stored in the same place with other organic solvents, let alone contact with organic solvents.

2. During transportation, the surface protective film or protective paper cannot be scratched.

3. It cannot be used in an environment where the temperature exceeds 85°C.

4. When cleaning the acrylic sheet, only 1% soapy water is needed. Use a soft cotton cloth dipped in soapy water. Do not use hard objects or dry wipes, otherwise the surface will be easily scratched.

5. Acrylic plate has a large thermal expansion coefficient, so the expansion gap should be reserved due to temperature changes.

2. During transportation, the surface protective film or protective paper cannot be scratched.

3. It cannot be used in an environment where the temperature exceeds 85°C.

4. When cleaning the acrylic sheet, only 1% soapy water is needed. Use a soft cotton cloth dipped in soapy water. Do not use hard objects or dry wipes, otherwise the surface will be easily scratched.

5. Acrylic plate has a large thermal expansion coefficient, so the expansion gap should be reserved due to temperature changes.

What is the application of acrylic sheet ?

1. Architectural applications: shop windows, soundproof doors and windows, lighting shades, telephone booths, etc.

2. Advertising applications: light boxes, signs, signs, display racks, etc.

3. Transportation applications: doors and windows of trains, automobiles and other vehicles.

4. Medical applications: baby incubators, various surgical medical appliances, civilian products: bathroom facilities, handicrafts, cosmetics, brackets, aquariums, etc.

5. Industrial applications: instrument surface panels and protective covers, etc.

6. Lighting applications: fluorescent lamps, chandeliers, street lampshades, etc.

7.Acrylic sheet for fish tank,Acrylic sheet for swimming pool.

2. Advertising applications: light boxes, signs, signs, display racks, etc.

3. Transportation applications: doors and windows of trains, automobiles and other vehicles.

4. Medical applications: baby incubators, various surgical medical appliances, civilian products: bathroom facilities, handicrafts, cosmetics, brackets, aquariums, etc.

5. Industrial applications: instrument surface panels and protective covers, etc.

6. Lighting applications: fluorescent lamps, chandeliers, street lampshades, etc.

7.Acrylic sheet for fish tank,Acrylic sheet for swimming pool.

What is the different cols of acrylic sheet?

he acrylic sheet is easy to dye,so there are different cols of acrylic sheet,such as clear acrylic sheet;black acrylic sheet;white acrylic sheet;colourful acrylic sheet;iridescent acrylic sheeet;textured acrylic sheet;colored acrylic sheet;opaque acrylic sheet;translucent acrylic sheet and so on. If you want see our col catalogue,please contact with me,we can provide acrylic col catalogue for free.

What size acrylic sheet can you do?

We can provide variety size of acrylic sheet,here is the most common size for your reference / 4*8 acrylic sheet / acrylic sheet cut to size / 24 x 36 acrylic sheet / 48 x 96 acrylic sheet

What is the thickness of acrylic sheet can you make?

The thickness we can make is from 1mm to 200mm,the below thickness is what we normally make. 1mm acrylic sheet / 2mm acrylic sheet / 1/2 inch acrylic sheet / 1/8 acrylic sheet / 1/4 inch acrylic sheet / 3/8 inch acrylic sheet / 3/16 acrylic sheet / 3mm acrylic sheet

What is the different types of acrylic sheet?

here are different types of acrylic sheets,such as extrude acrylic sheet;cast acrylic sheet;acrylic mirror sheet;acrylic thick sheet;acrylic thin sheet;opaque acrylic sheet;glitter acrylic sheet;two color acrylic sheet.HSQY plastic group is the famous acrylic manufacturer in China,our quality and service are competitive in the market,you are welcome to contact with us.

Get The Latest Price Or Free Sample,Contact With Us.

PRODUCTS

PET SheetPVC Rigid SheetPVC Soft FilmPVC Foam BoardAcrylic SheetAPPLICATION

ThermoformingPrintFood PackagingPharmaceutical PackagingPHONE NUMBER: 0086-15895068369EMAIL: vivi@hgqyplastic.comAdd:11th floor,HUASHENG BUILDING ZhongLou District,ChangZhou City,JiangSu Province,China,213001ABOUT US

NEWSFAQDownloadSOCIAL MEDIA

LinkedinYoutubeTwitterFacebook

vivi@hgqyplastic.com

vivi@hgqyplastic.com