Product Categories

PET PLASTIC SHEET

PET PLASTIC SHEET

APET Sheet

PETG Sheet

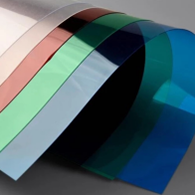

PVC RIGID SHEET

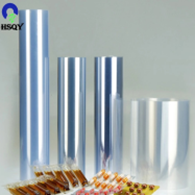

PVC SOFT FILM

PVC SOFT FILM

PVC FOAM BOARD

PVC FOAM BOARD

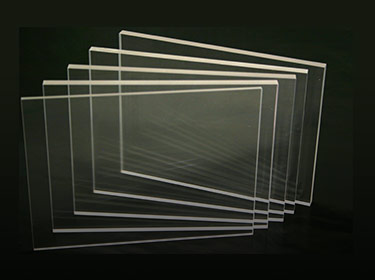

ACRYLIC SHEET

ACRYLIC SHEET

FOOD TRAY

FOOD TRAY

Welcome to HSQY Plastic Group - Your Trusted Partner in Plastic Materials for Over 18 Years!

At HSQY Plastic Group, a seasoned manufacturer and trader in China for 18 years, we specialize in providing high-quality plastic materials. With a focus on PET, PVC, and CPET, we excel in delivering innovative solutions for the B2B market. Our commitment to excellence has made us a trusted partner for businesses across industries.

High chemical stability, fine anti-fire, super-transparent. Highly UV.stabilized, good mechanical properties, high hardness and strength. The sheet also has well aging resistance, good self-extinguishing property and reliable insulativity. Moreover the sheet is waterproof and has very good smooth surface and is non deformable. Application: chemical industry, oil industry, galvanization, water purification equipments, environment protection equipments, medical appliance and so on. Important item: the sheet anti-stastic, anti-UV, anti-sticky.

1. High Impact:

Our sheets has high impact feature, it's has strong strength, and can be used in special space.

2. Anti-UV:

We can do anti-uv on the surface of the PVC Sheet, to make the produce anti-yellow when we use outside for years.

3. Anti-fire:

PVC is a kind of anti-fire product naturally, people no need to consider about the fire when we use it.

4. Crystal-Clear surface: Our Rigid PVC Film/Sheet for Molding Vacuum forming and Printing is characterized by crystal-clear clarity. This feature ensures that your molded products maintain the highest visual appeal, making them perfect for applications.

5. Dimensional Stability: Achieve consistent results with our Rigid PVC Film/Sheet, thanks to its exceptional dimensional stability. We have big range thickness and customized Size in roll or sheet.

Thickness Options: Available in various thickness(0.07-5mm), our Rigid PVC Film/Sheet allows you to choose the ideal gauge for your specific application. From thin films for intricate molding to thicker sheets for robust packaging, we have you covered.

| Size by sheet | customized |

| Width limitation | width<=1280mm |

| Thickness by sheet | 0.2mm/0.25mm/0.3mm |

| Density | 1.36-1.38 g/㎤ |

| Color | Clear,green,brown,white,yellow,red |

| Tensile strength | >52 MPA |

| Impact strength | >5 KJ/㎡ |

| Drop impact strength | no fracture |

| Softening temperature | >52 MPA |

| Decoration plate | >75 ℃ |

| Industrial plate | >80 ℃ |

| Clear PVC Rigid Sheet | Transparent Colored PVC Sheet | Opaque Colored PVC Roll |

|  |  |

| PVC Stationery Sheet | PVC Folding Sheet | PVC Medical/Pharma Film |

|  |  |

| PVC Vacuum Forming Film | PVC Christmas/Fence Film | PVC Poker Sheet |

|  |  |

Box Packaging: Our Rigid PVC Film/Sheet is a preferred choice for box packaging, especially in the production of normal Household product packaging and toy packing. Benefit from the material's durability, clarity, and suitability for various designs.

Medical Devices: Ensure the integrity of medical device packaging with our Rigid PVC Film/Sheet. Its sterile properties, combined with precise forming capabilities, make it an ideal choice for medical packaging solutions.

Consumer Goods: Elevate the visual appeal of consumer goods through detailed and clear packaging. Our Rigid PVC Film/Sheet caters to diverse industries, from electronics to cosmetics.

Versatile Forming Capability: Engineered for precision, our Rigid PVC Film/Sheet effortlessly adapts to Molding Vacuum forming and Printing processes. This versatility allows you to explore various manufacturing techniques without compromising on quality.

1. Extruded: In the hopper of the extruder, the heated PVC resin raw material is added and subjected to high temperature and high pressure. Heated and compressed, it is extruded into a plastic melt with relatively good fluidity. At this time, the meltThe PVC granulating extruder operates stably and mixes evenly and extrudes it through the die to form a long strip of plastic film. The width and thickness of the film are stretched and adjusted through traction rollers, guide rollers and other auxiliary devices to make it have better properties. Smoothness and uniformity.

2. Calender: PVC resin needs to be calendered to eliminate internal stress, improve its flatness and roughness and ensure it meets user requirements and standards. In the calendering process, the film needs to go through 2-4 sets of pressure rollers to ensure good flatness and dimensional accuracy, and can also be used to change its surface condition and gloss.

PVC Film extrusion calendering is a commonly used plastic processing process. It extrudes molten plastic into A continuous production process is formed by forming a film and then using the action of the pressure roller to make it flat and uniform production process.

Difference: Range of thickness is different; transparency is different.

Plasticizing

Film coating

Sheet cutting

Bag packing

Pallet packing

Container load

Thickness Range: 0.05-10mm: We can produce the thickness from 0.05-10mm, depends on the request of our clients

Width and Length: customized size in roll or in sheet: Normally our sheet size: 1220*2440mm; 915*1830mm, and film in rolls with size 610mm etc.

Density: 1.36g/cm3 for Extruded, 1.37g/cm3 for Calender

Color: Transparent Clear with glossy/matt surface, also we can produce different colors, like red, blue, green, yellow, etc

Min order: at least 1000 kgs due to the characteristic of our product, color pvc min order should be at least 2000 kgs. And we need the color sample from our client, so we can produce the color accordingly

Application: Packing; Vacuum forming; Folding Box; Printing; Construction; Window Patch

The most popular usage: vacuum forming and printing, uv printing, silky printing and offset printing.

Recognizing the unique needs of every client, HSQY Plastic Group offers customization options for our Rigid PVC Film/Sheet. Tailor the specifications to match your project requirements seamlessly.

Contact our dedicated team today to discuss your requirements and explore how our PVC sheets can elevate your business to new heights. Trust HSQY Plastic Group – Your Gateway to Quality and Versatility in PVC solutions. At HSQY Plastic Group, we are dedicated to meeting the demands of our partners with top-notch Frosted Acrylic Sheets that blend functionality, durability, and aesthetic appeal seamlessly. Contact us today to discuss your project needs and experience the difference with our premium acrylic solutions.