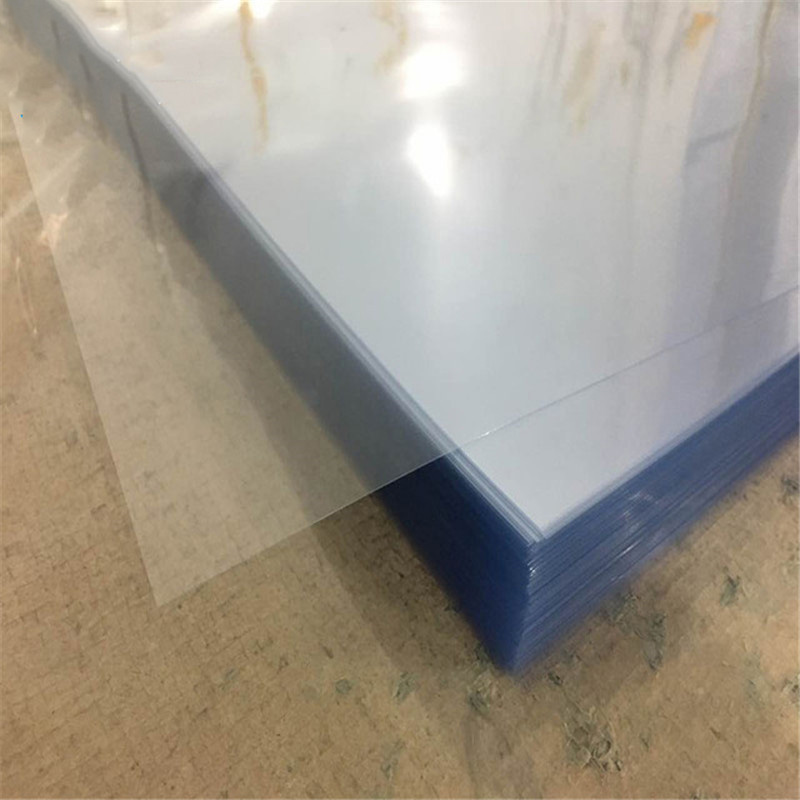

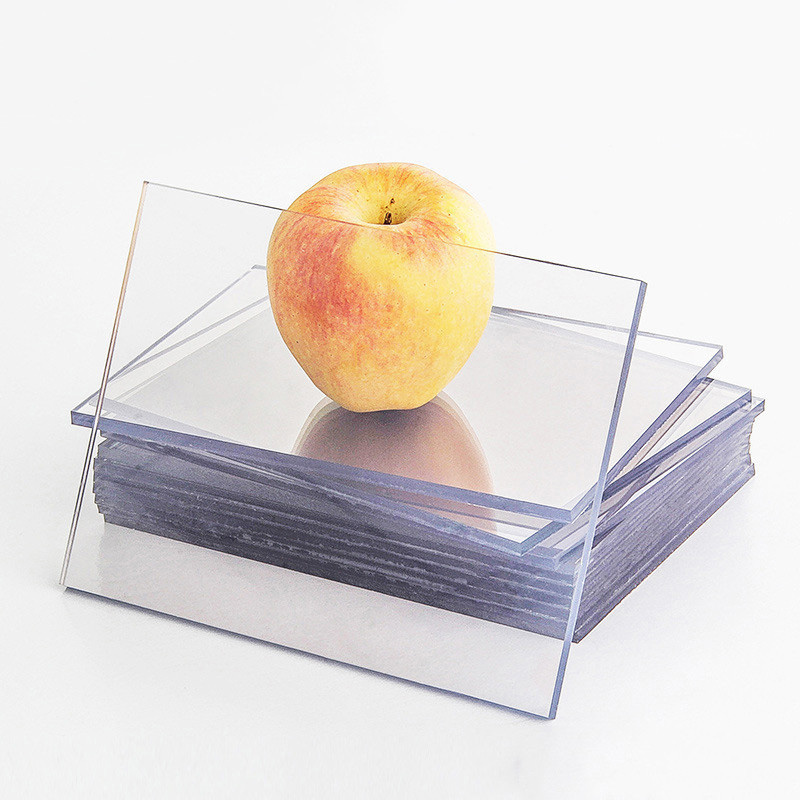

PVC plastic sheet is a kind of application material with excellent performance, and it can be used everywhere in our daily life. PVC material is cheap, easy to process, corrosion resistant, and it is also a good insulating material.

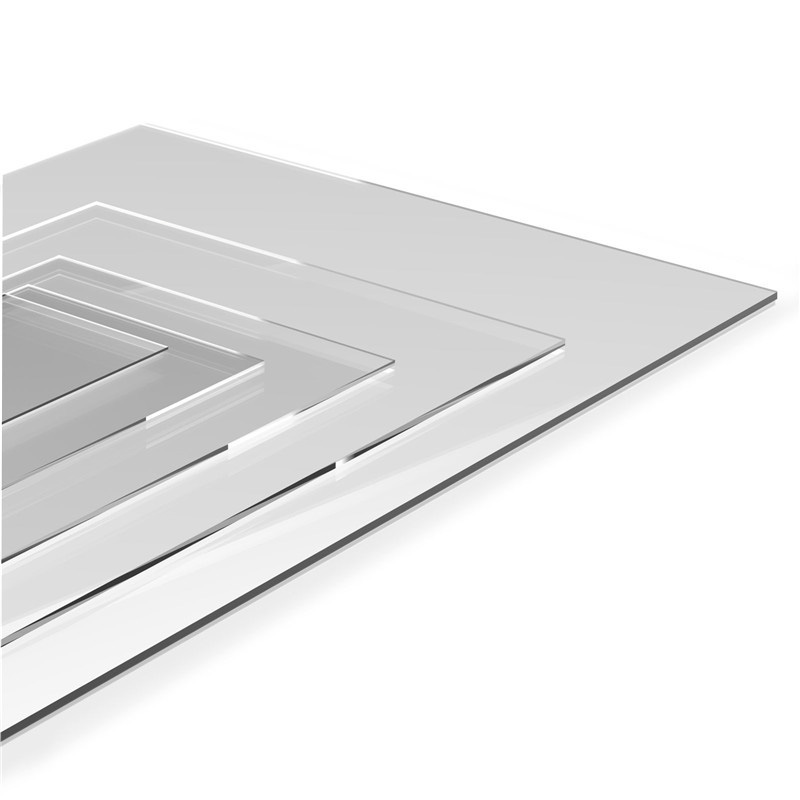

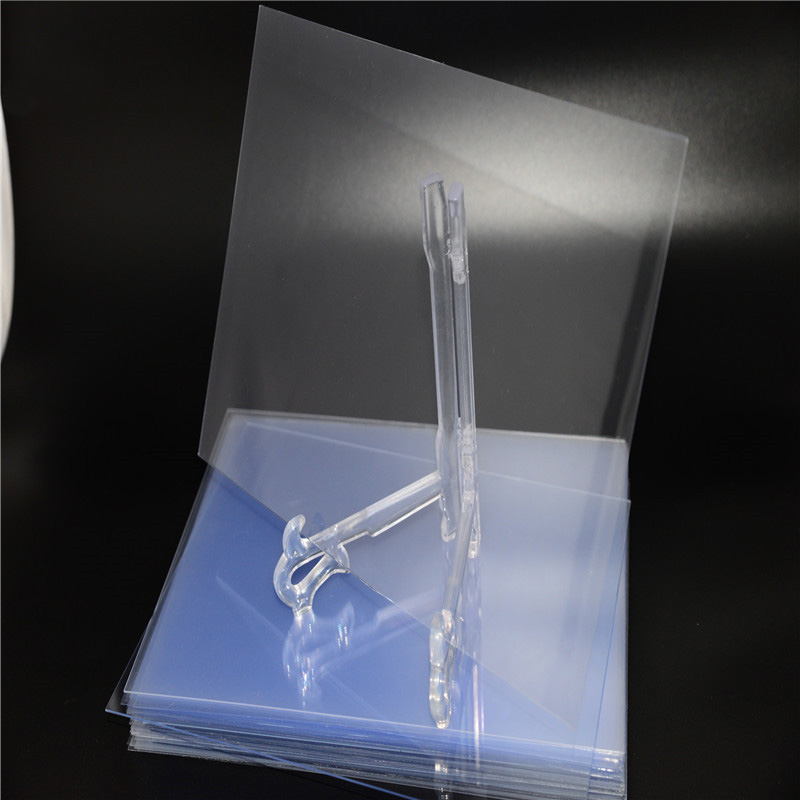

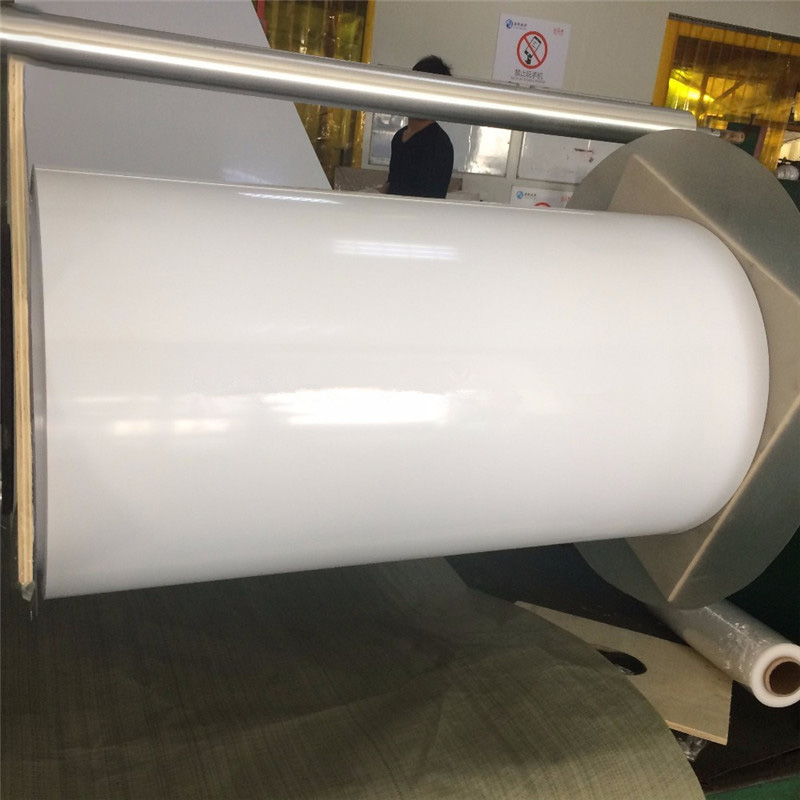

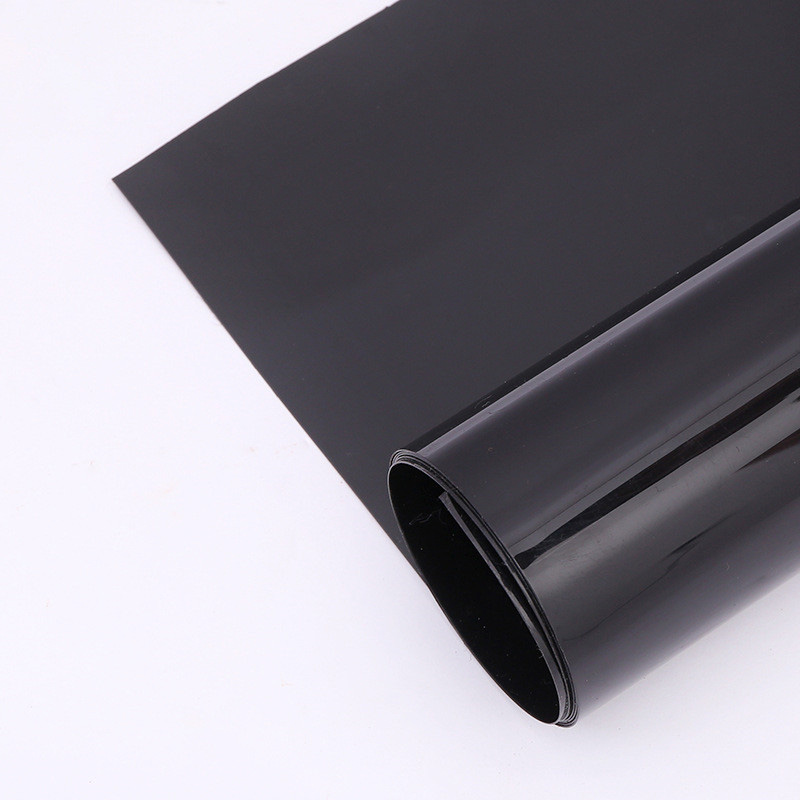

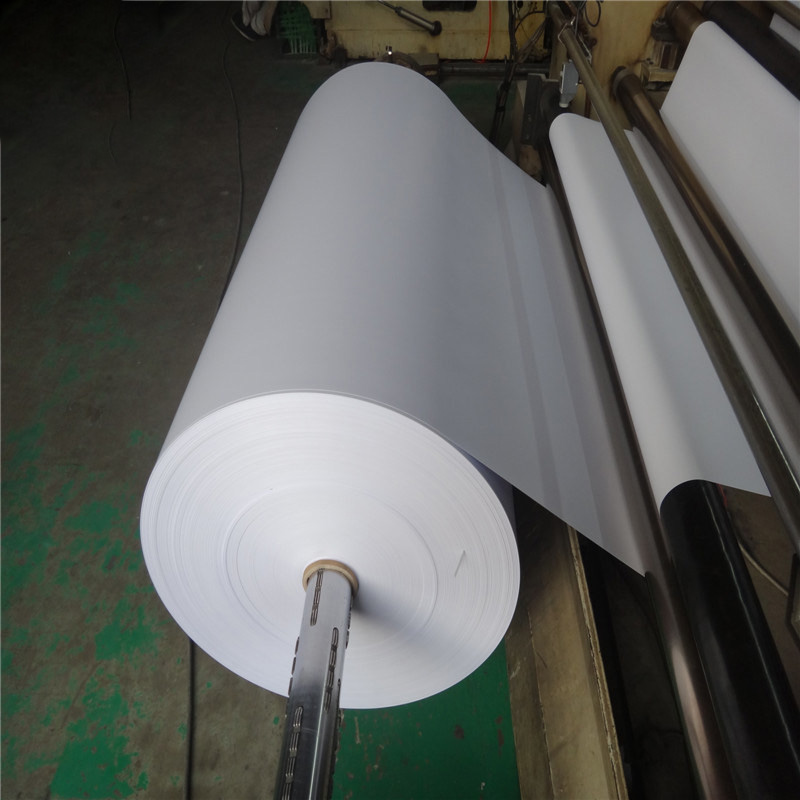

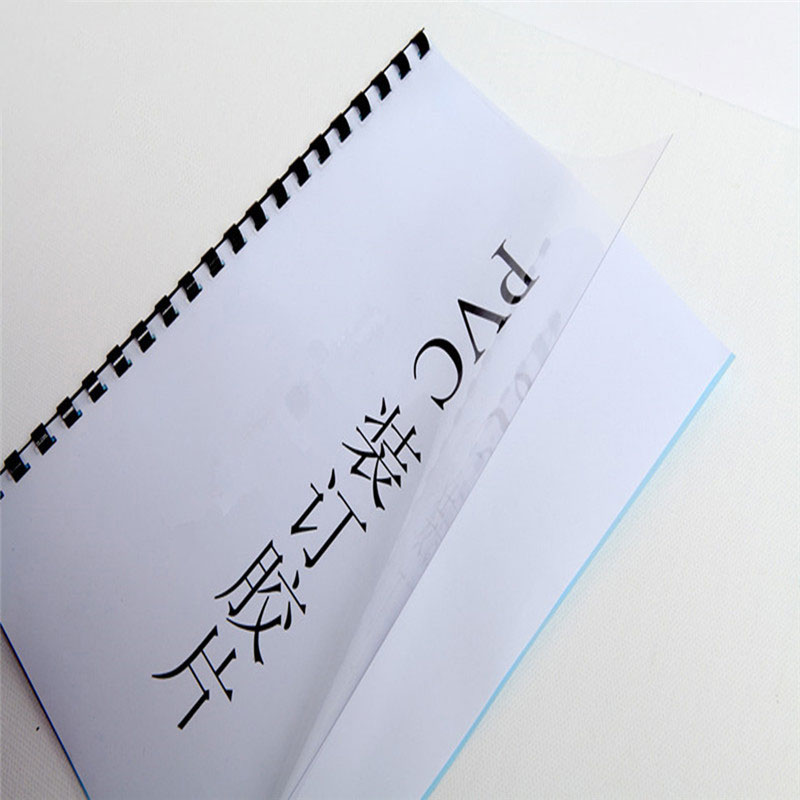

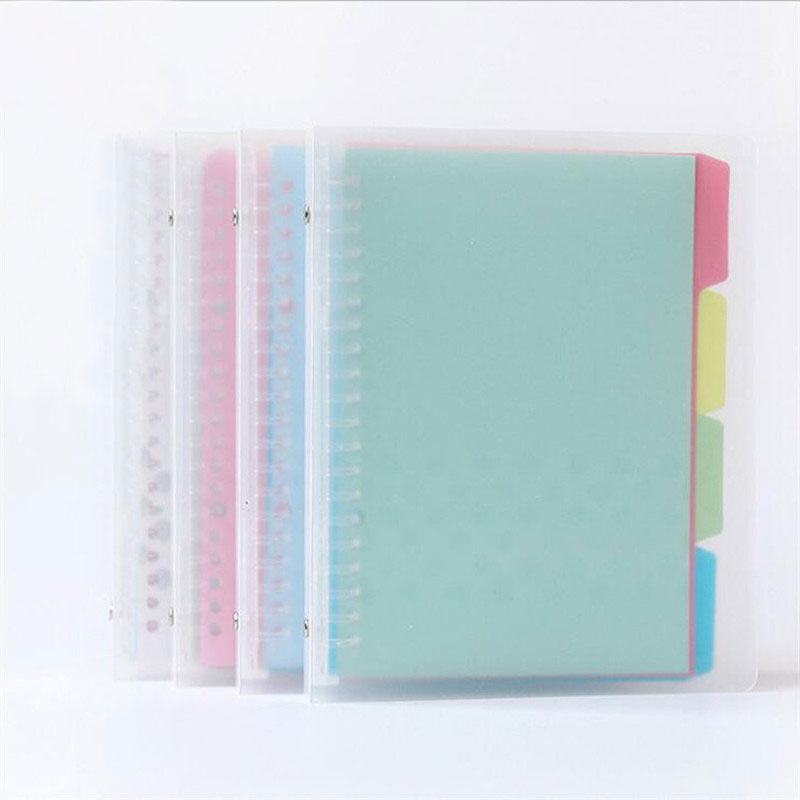

According to the production process, PVC sheet plastic can be divided into PVC extruded sheet and PVC calendered sheet. According to the color, there are clear PVC sheet, white PVC sheet, black PVC sheet, matt PVC sheet, and so on. According to the application, there are PVC Christmas films, PVC film for pharmaceutical packaging, Rigid PVC Film Thermoforming Grade, a4 PVC binding sheet, and so on.

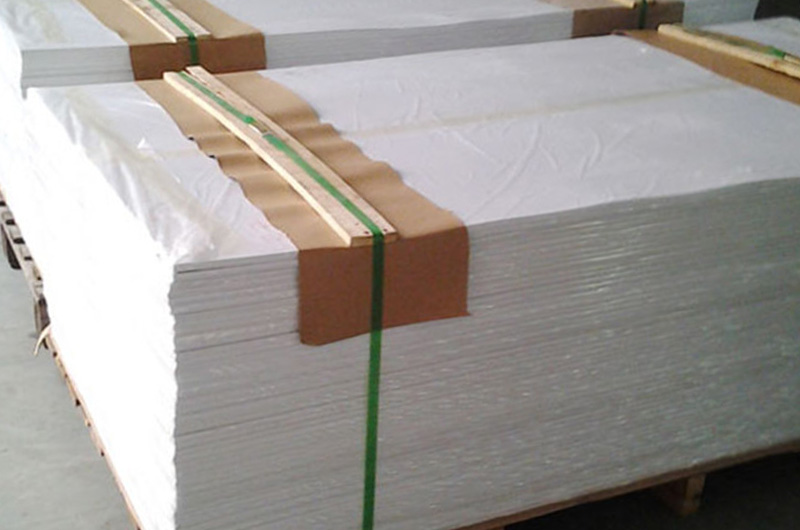

Format:

Sheet: 700x1000mm; 915x1830mm; 1220x2440mm

Roll: width: 80-1220mm

Density:

Clear: 1.36-1.37g/cm3

Color: 1.4g/cm3

PVC RIGID SHEET

FUNDAMENTAL PVC SHEET ATTRIBUTES

Product Advantages

1. Customization Capabilities: Recognizing the unique needs of our B2B customers, we offer customization options for color, size, and surface finish. Tailor our PVC Rigid Film/Sheet to match your brand identity and project requirements.

2. Eco-Friendly Solutions: At HSQY Plastic Group, we are committed to sustainability. Our PVC Rigid Film/Sheet is designed with eco-friendly considerations, ensuring a balance between performance and environmental responsibility.

2. Eco-Friendly Solutions: At HSQY Plastic Group, we are committed to sustainability. Our PVC Rigid Film/Sheet is designed with eco-friendly considerations, ensuring a balance between performance and environmental responsibility.

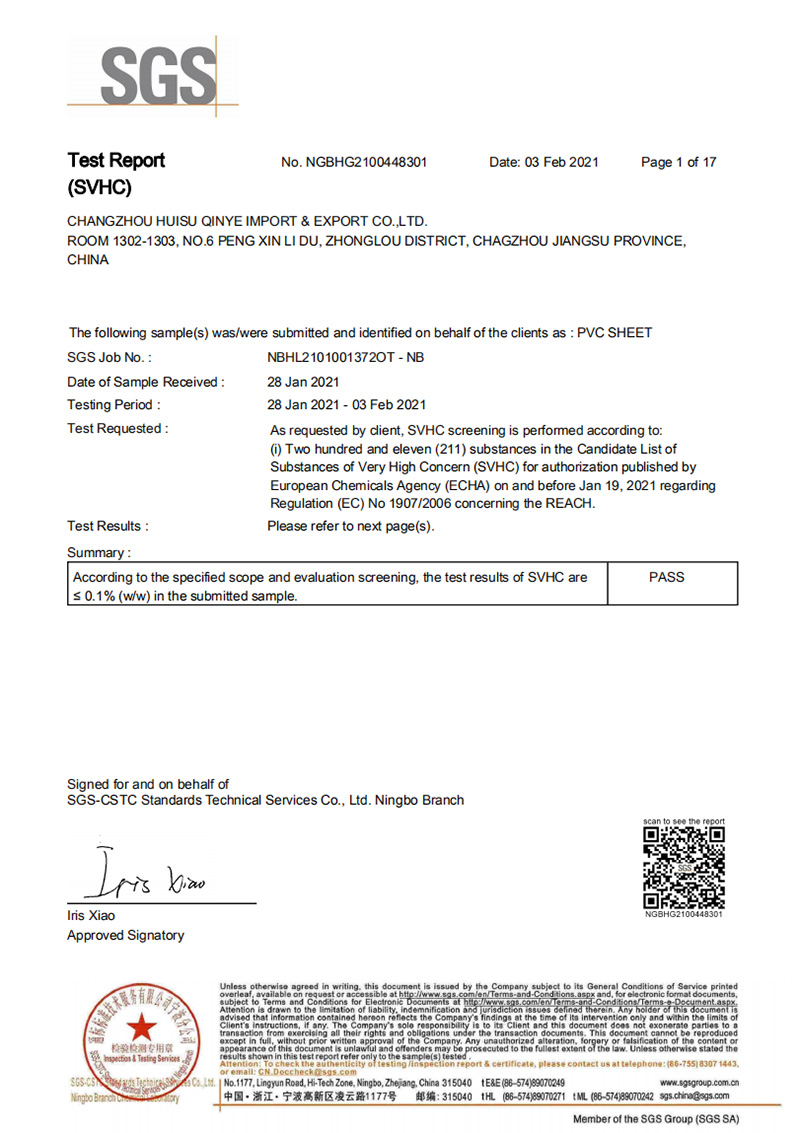

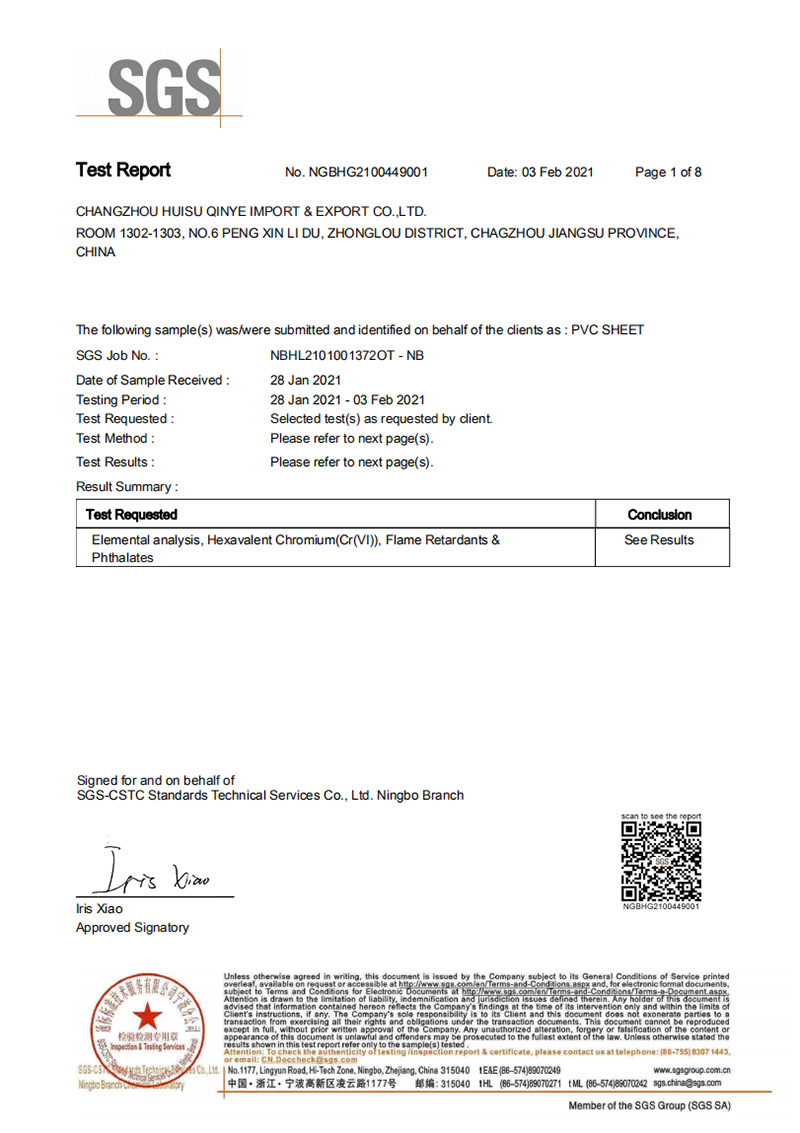

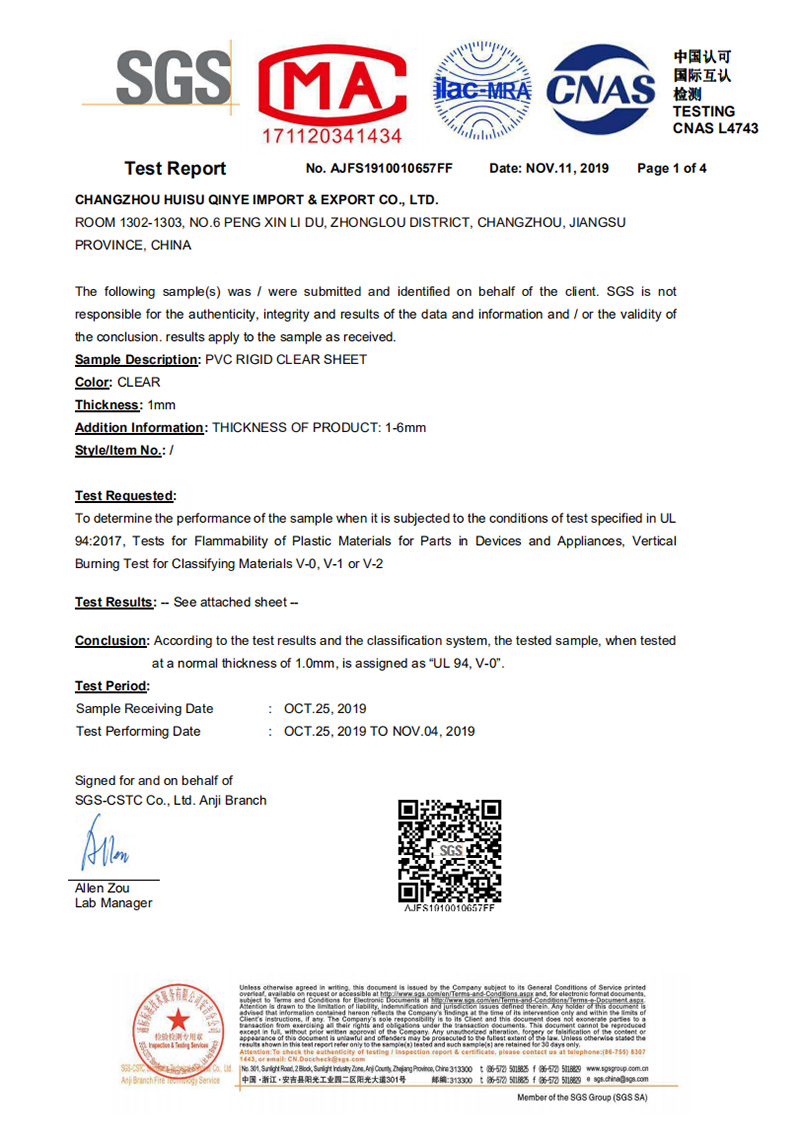

CERTIFICATE

Our PVC rigid sheet are widely used as below Main Applications:

1. Packaging: PVC clear sheet or roll, due to its super clear transparency, so are widely used for vacuum forming, folding box, for packaging use.

2. Printing: Its smooth and matt surface can meet different printing ways, such as UV printing, silk printing, offset printing and so on.

3. Construction and Building: Elevate your construction projects with our robust PVC Rigid Sheet. Its structural integrity and weather resistance make it a valuable component in building materials, providing both aesthetics and functionality.

4. Electronic field: PVC is widely used in the electronic field, such as wire insulation, electronic component packaging, etc. It has excellent electrical insulation properties and processing properties, providing reliable protection for electronic products.

5. Medical field: PVC is widely used in the medical field, such as medical equipment, pharmaceutical packaging, etc. It is non-toxic, tasteless, corrosion-resistant, etc., providing a safe and reliable guarantee for the medical industry.

PVC rigid sheet/film also can be used as PVC binding cover, PVC fence grass, Christmas tree and so on.

2. Printing: Its smooth and matt surface can meet different printing ways, such as UV printing, silk printing, offset printing and so on.

3. Construction and Building: Elevate your construction projects with our robust PVC Rigid Sheet. Its structural integrity and weather resistance make it a valuable component in building materials, providing both aesthetics and functionality.

4. Electronic field: PVC is widely used in the electronic field, such as wire insulation, electronic component packaging, etc. It has excellent electrical insulation properties and processing properties, providing reliable protection for electronic products.

5. Medical field: PVC is widely used in the medical field, such as medical equipment, pharmaceutical packaging, etc. It is non-toxic, tasteless, corrosion-resistant, etc., providing a safe and reliable guarantee for the medical industry.

PVC rigid sheet/film also can be used as PVC binding cover, PVC fence grass, Christmas tree and so on.

0

0Shopping Cart

Delete all items

Proceed to send inquiry

PVC SHEET PRODUCTS

The development trend of PVC

- With the continuous improvement of environmental awareness, the PVC industry is developing in the direction of environmental protection.At present, many manufacturers have begun to use environmentally friendly PVC materials, such as biodegradable PVC, thermoplastic biodegradable plastics, etc. These materials are environmentally friendly and degradable, which can effectively reduce environmental pollution. In addition, some new PVC alternatives are emerging, such as polypropylene (PP), polyethylene (PE), etc. These alternatives have better environmental performance and a wider range of applications, bringing new challenges and opportunities to the PVC industry.

In short, PVC, as a widely used plastic material, has a variety of excellent properties. It plays an important role in construction, furniture, automotive, electronics, medical, and more. However, with the increasing awareness of environmental protection and the continuous emergence of new materials, the PVC industry will face new challenges and opportunities. In the future, we need to pay more attention to environmental protection and sustainable development, and constantly develop new PVC alternatives to better serve the development needs of human society.

OUR FACTORY

HSQY Plastic Group - Your Trusted Partner for PVC Rigid Film/Sheet Solutions Explore

We established in year 2008,more than 15 years in this market,to offer you professional product and best price to support you!

Since its establishment, the company has been committed to providing high-quality PVC sheet products to customers around the world and focusing on expanding the international market. With its expertise and experience, Global PVC Export has gradually become a global leader in this field.

Welcome to HSQY Plastic Group, your premier source for top-quality PVC Rigid Film/Sheet solutions tailored to meet the diverse needs of global industries. As a leading PVC sheet supplier in the market, we take pride in offering innovative products that redefine standards and elevate your projects.

We established in year 2008,more than 15 years in this market,to offer you professional product and best price to support you!

Since its establishment, the company has been committed to providing high-quality PVC sheet products to customers around the world and focusing on expanding the international market. With its expertise and experience, Global PVC Export has gradually become a global leader in this field.

Welcome to HSQY Plastic Group, your premier source for top-quality PVC Rigid Film/Sheet solutions tailored to meet the diverse needs of global industries. As a leading PVC sheet supplier in the market, we take pride in offering innovative products that redefine standards and elevate your projects.

Why Choose HSQY

1. Quality Assurance: Rest assured with our commitment to stringent quality control measures. Our PVC Rigid Film/Sheet adheres to international quality standards, providing you with reliable and consistent performance.

2. Supply Chain Efficiency: HSQY Plastic Group takes pride in its efficient global supply chain. Timely deliveries, streamlined logistics, and responsive customer support are the cornerstones of our service.

3. Technical Support: Gain access to our technical expertise and support throughout your project lifecycle. From product selection to application guidance, our team is dedicated to ensuring your success.

Connect with HSQY Plastic Group

Choose HSQY Plastic Group as your trusted partner for PVC Rigid Film/Sheet solutions. Explore the possibilities of our superior products, and let us contribute to the success of your projects.

Contact us today to discuss your requirements, request samples, or receive a personalized quote. We look forward to building a lasting partnership with your esteemed organization.

Our customer support team is committed to providing seamless assistance throughout your procurement journey. From product inquiries to post-purchase support, we are here to ensure your satisfaction.

2. Supply Chain Efficiency: HSQY Plastic Group takes pride in its efficient global supply chain. Timely deliveries, streamlined logistics, and responsive customer support are the cornerstones of our service.

3. Technical Support: Gain access to our technical expertise and support throughout your project lifecycle. From product selection to application guidance, our team is dedicated to ensuring your success.

Connect with HSQY Plastic Group

Choose HSQY Plastic Group as your trusted partner for PVC Rigid Film/Sheet solutions. Explore the possibilities of our superior products, and let us contribute to the success of your projects.

Contact us today to discuss your requirements, request samples, or receive a personalized quote. We look forward to building a lasting partnership with your esteemed organization.

Our customer support team is committed to providing seamless assistance throughout your procurement journey. From product inquiries to post-purchase support, we are here to ensure your satisfaction.

PRODUCTION STATUS

5-10 DAYS

<10tons

10-15 DAYS

10-20tons

15-20 DAYS

20-50tons

>20 DAYS

>50tons

F&Q

- 1-5

- 6-7

- What is PVC plastic sheet?

- PVC rigid sheet also called Polyvinyl Chloride Sheet. Using PVC resin powder as raw materials, it has strong performance in anti-oxidation, anti-strong acid. PVC rigid sheet also with high strength and excellent stability, and is VO grade Flame retardant.

- What is 5 biggest PVC rigid sheet manufacture in China?

- Jiangsu Jincai Polymer Materials Science And Technology Co., Ltd.

Changzhou Huisu Qinye Plastic Group

Jiangsu Jiujiu Material Technology Co., Ltd.

Jiangsu Jumai New Material Technology Co., Ltd.

Yiwu Haida Plastic Industry Co., Ltd. - What is application of PVC rigid sheet?

- Due to good processing properties of PVC sheet, low material costs, PVC sheets have extremely wide range of uses, mainly used to make PVC Christmas Tree Film;PVC Green film to make fence;PVC report covers; PVC name cards;PVC boxes; PVC foam board,PVC ceiling, PVC playing card material and PVC rigid sheet for blister.

- What is the most common thickness of PVC sheet?

- This depends on your requirement,we can make it from 0.12MM to 10MM. The most common customer use are 1/2 inch pvc sheet / 2mm pvc sheet / 4mm pvc sheet / 6mm pvc sheet / 3mm black pvc sheet / black pvc sheet / white pvc sheet

- What is most common usage of PVC sheet?

- PVC plastic sheet has a wide range of uses and is one of the most commonly used plastics in our daily lives. Such as PVC rigid sheet for Thermoforming.

PVC film for pharmaceutical packaging

Laminated PVC/PE film for pharmaceutical packaging

PVC adhesive photo album sheet

PVC green film for Christmas tree film

PVC green film for artificial grass fence

PVC plastic sheet for playing cards

PVC rigid sheet for garment template

PVC transparent sheet for bending cover

Colourful PVC sheet for bending cover

Matt PVC sheet for printing

PVC/PVDC Films For Pharmaceutical Packaging PVC - What is the most common thickness of PVC plastic sheet?

- There are different thickness of PVC plastic sheet,HSQY plastic group is the leading PVC plastic sheet factory,can make PVC sheet thickness from 0.1MM to 10MM,Here is the most common thickness of PVC sheet. 3mm pvc sheet / 6mm pvc sheet / 2mm pvc sheet / 1mm pvc sheet / 4mm pvc sheet / 5mm pvc sheet

- Where to buy PVC sheet?

- HSQY plastic group is the leading PVC plastic sheet supplier in China ,we supply many kinds of PVC plastic sheet.You can also find PVC plastic suppliers in below factory

Changzhou Huisu Qinye Plastic Group.

Zhejiang Zhongsheng New Material Technology Co., Ltd.

Jiangsu Jumai New Material Technology Co., Ltd.

Shanghai Mihan New Material Technology Co., Ltd.

What is PVC plastic sheet?

PVC rigid sheet also called Polyvinyl Chloride Sheet. Using PVC resin powder as raw materials, it has strong performance in anti-oxidation, anti-strong acid. PVC rigid sheet also with high strength and excellent stability, and is VO grade Flame retardant.

What is 5 biggest PVC rigid sheet manufacture in China?

Jiangsu Jincai Polymer Materials Science And Technology Co., Ltd.

Changzhou Huisu Qinye Plastic Group

Jiangsu Jiujiu Material Technology Co., Ltd.

Jiangsu Jumai New Material Technology Co., Ltd.

Yiwu Haida Plastic Industry Co., Ltd.

Changzhou Huisu Qinye Plastic Group

Jiangsu Jiujiu Material Technology Co., Ltd.

Jiangsu Jumai New Material Technology Co., Ltd.

Yiwu Haida Plastic Industry Co., Ltd.

What is application of PVC rigid sheet?

Due to good processing properties of PVC sheet, low material costs, PVC sheets have extremely wide range of uses, mainly used to make PVC Christmas Tree Film;PVC Green film to make fence;PVC report covers; PVC name cards;PVC boxes; PVC foam board,PVC ceiling, PVC playing card material and PVC rigid sheet for blister.

What is the most common thickness of PVC sheet?

This depends on your requirement,we can make it from 0.12MM to 10MM. The most common customer use are 1/2 inch pvc sheet / 2mm pvc sheet / 4mm pvc sheet / 6mm pvc sheet / 3mm black pvc sheet / black pvc sheet / white pvc sheet

What is most common usage of PVC sheet?

PVC plastic sheet has a wide range of uses and is one of the most commonly used plastics in our daily lives. Such as PVC rigid sheet for Thermoforming.

PVC film for pharmaceutical packaging

Laminated PVC/PE film for pharmaceutical packaging

PVC adhesive photo album sheet

PVC green film for Christmas tree film

PVC green film for artificial grass fence

PVC plastic sheet for playing cards

PVC rigid sheet for garment template

PVC transparent sheet for bending cover

Colourful PVC sheet for bending cover

Matt PVC sheet for printing

PVC/PVDC Films For Pharmaceutical Packaging PVC

PVC film for pharmaceutical packaging

Laminated PVC/PE film for pharmaceutical packaging

PVC adhesive photo album sheet

PVC green film for Christmas tree film

PVC green film for artificial grass fence

PVC plastic sheet for playing cards

PVC rigid sheet for garment template

PVC transparent sheet for bending cover

Colourful PVC sheet for bending cover

Matt PVC sheet for printing

PVC/PVDC Films For Pharmaceutical Packaging PVC

What is the most common thickness of PVC plastic sheet?

There are different thickness of PVC plastic sheet,HSQY plastic group is the leading PVC plastic sheet factory,can make PVC sheet thickness from 0.1MM to 10MM,Here is the most common thickness of PVC sheet. 3mm pvc sheet / 6mm pvc sheet / 2mm pvc sheet / 1mm pvc sheet / 4mm pvc sheet / 5mm pvc sheet

Where to buy PVC sheet?

HSQY plastic group is the leading PVC plastic sheet supplier in China ,we supply many kinds of PVC plastic sheet.You can also find PVC plastic suppliers in below factory

Changzhou Huisu Qinye Plastic Group.

Zhejiang Zhongsheng New Material Technology Co., Ltd.

Jiangsu Jumai New Material Technology Co., Ltd.

Shanghai Mihan New Material Technology Co., Ltd.

Changzhou Huisu Qinye Plastic Group.

Zhejiang Zhongsheng New Material Technology Co., Ltd.

Jiangsu Jumai New Material Technology Co., Ltd.

Shanghai Mihan New Material Technology Co., Ltd.

Get The Latest Price Or Free Sample,Contact With Us.

PRODUCTS

PET SheetPVC Rigid SheetPVC Soft FilmPVC Foam BoardAcrylic SheetAPPLICATION

ThermoformingPrintFood PackagingPharmaceutical PackagingPHONE NUMBER: 0086-15895068369EMAIL: vivi@hgqyplastic.comAdd:11th floor,HUASHENG BUILDING ZhongLou District,ChangZhou City,JiangSu Province,China,213001ABOUT US

NEWSFAQDownloadSOCIAL MEDIA

LinkedinYoutubeTwitterFacebook

vivi@hgqyplastic.com

vivi@hgqyplastic.com