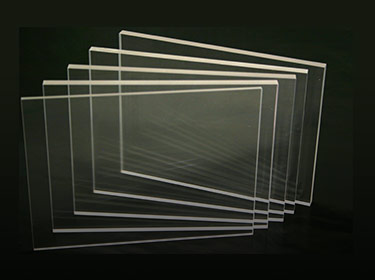

PET VS PVC IN FOOD PACKAGING

It is becoming increasingly common to see customers demanding the use of PET (Polyethylene terephthalate) in food packaging instead of the traditional PVC (Polyvinyl chloride), but why the sudden change? Ultimately, it comes down to which of the two is more environmentally friendly and of course, the cost.

Physically, both PET and PVC have similar characteristics, but there are a few key elements where PET outperforms its predecessor. It has a higher thermal conductivity, which ultimately means it requires less energy to mould it when thermoforming and a quicker cycle time. Another key environmental edge that PET has over PVC is that it can be recycled much more easily, PET regrind can be used to return to sheet whereas PVC regrind is much more difficult and expensive to use.

When looking at the direct cost, PET and PVC are similarly priced, so surely this makes PET the clear winner due to its environmental advantage, right? Not necessarily. It isn't just the direct cost of the two materials that needs to be considered, there are many other costs related to the use of PET over PVC that can have a big impact on the user.

One such area that we are familiar with, is the wear on die cutting equipment. PET is a tougher structure, which means is requires more force, more accuracy and inflicts more wear on the tooling when cutting. To counteract this, the steel used in die cutting needs to be stronger, the profile needs to be sharper, and the pressure needs to be increased, among other things. RPET (Recycled PET) can often be even more difficult to cut.

Both PET and PVC have their advantages, but with its environmental benefits it's clear to see why many supermarket chains are now insisting their products are packaged in PET instead of PVC. What's not so clear is the long term cost-effectiveness to the processing/packaging companies having to manage PET on a daily basis, only time will tell.

vivi@hgqyplastic.com

vivi@hgqyplastic.com