PVC film roll suppliers explain common problems in the production

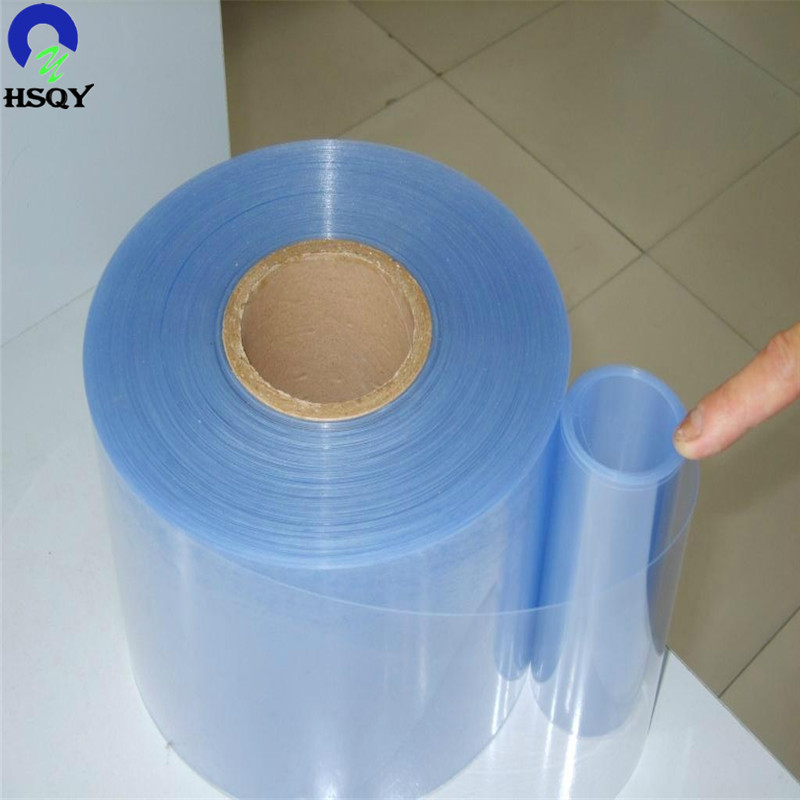

The main components of PVC are polyvinyl chloride, among others, to increase its heat resistance and ductility. The top layer of PVC membrane is a coat of paint, the middle layer is polyvinyl chloride, and the bottom layer is a back coating adhesive. From the perspective of PVC film roll suppliers, PVC film roll is a widely used synthetic material.

PVC film roll suppliers use the medium to high-density substrates to process PVC film roll into a variety of lines, and then blister, various matte bloom, different colors, and different textures of PVC film roll, make the VC film roll produced by the variety is very rich, on the market look is dazzling. Of course, all products may have different characteristics, PVC film roll suppliers often have some small problems in production, if we encounter such problems, how do we need to solve them? Let’s talk about that in more detail.

PVC film roll may wrinkle during production for the following reasons:

1. The spacing between long and narrow workpieces is too small;

2. There are no corners chamfered around the backing plate;

3. The distance between the horizontal and vertical of the workpiece is not in a straight line, the resistance becomes larger;

4. The temperature set by the machine is too high;

5. The pressure set by the machine itself is too long.

PVC film roll may be white in production for the following reasons:

1. The temperature set by the machine itself is too high;

2. The pressure set by the machine itself is too long;

3. The lines are not set properly.

If found in the production of PVC membrane occurred in the above several cases, do not worry, timely adjustment of the machine can be done.

HSQY is a professional PET sheet factory, we specialize in providing you with high-quality PVC plastic sheets and related accessories. We support a global fast delivery service for your order. If you have any questions, please e-mail us at: vivi@hgqyplastic.com.

vivi@hgqyplastic.com

vivi@hgqyplastic.com