Welcome To Visit Our Factory

Huisu Qinye Plastic Group is a technology-based enterprise dedicated to the research, development, manufacturing and sales of biodegradable materials. Biodegradable products currently exported include school biodegradable lunch trays, biodegradable trays with lids, and biodegradable box cakes.

PRODUCTION STATUS

5-10 DAYS

<10tons

10-15 DAYS

10-20tons

15-20 DAYS

20-50tons

>20 DAYS

>50tons

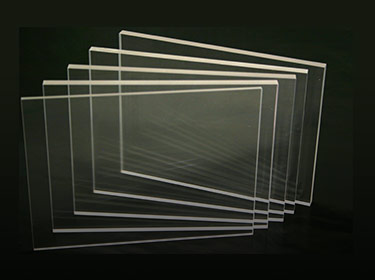

HUISU QINYE PLASTIC has more than 20+ of plastic production lines, our monthly capacity is 5000tons,we supply PVC sheet, PET sheet/film, acrylic sheet and so on.

FAQ

- 1-3

- What material is polylactic acid (PLA)?

- Polylactic acid (PLA) is a bio-based and biodegradable polymer made from annually renewable resources.

Polylactic acid(PLA) is a thermoplastic aliphatic polyester. The lactic acid or lactide required for the production of polylactic acid(PLA) can be obtained by fermentation, dehydration and purification of renewable resources.

Polylactic acid generally has good mechanical properties and processing properties, and polylactic acid products can be quickly degraded in various ways after being discarded, and are truly pollution-free. - What does bioplastic mean?

- Environmental Protection

Bioplastics made from annually renewable biomass reduce our carbon footprint and reduce our reliance on fossil resources. They also offer a variety of scrapping options.

Positive economic benefits

Consumers are becoming more aware of their environmental benefits and are increasingly favoring greener plastics. - Why Choose Polylactic Acid (PLA)?

- Bio-based PLA resin with multiple end-of-life options is made from renewable resources and is 100% bio-based according to EN16785-1. At the end of its useful life, polylactic acid (PLA) applications can be recycled mechanically or chemically. Polylactic acid (PLA) is also compostable according to EN13432. Compostable applications such as bin liners help divert valuable organic waste from landfills.

Efficient use of raw materials

PLA is a highly efficient plastic: it takes only 1.6 kg of sugar to make 1 kg of polylactic acid (PLA). Other types of bioplastics may require more natural resources to produce the same amount of final product.

Can be used on an industrial scale

PLA is commercially available on an industrial scale from several large factories around the world.

Proven Application

Commercial products made from PLA can already be found in a wide range of mature markets. Whether you are interested in molded parts, films, foams, 3D printing or fibers, you can turn to us for application development support.

PLA Products and Plastic Circular Economy

In a circular economy of PLA products, so-called "waste streams" and "end-of-life" products form the basis of new products, rather than being disposed of. This more holistic and sustainable approach replaces the linear economy with a circular bio-based economy in which products are produced from sustainable natural resources and reused and recycled wherever possible. At the end of their life cycle, these products have a range of options to convert them into new or value-added product life cycle feedstocks.

Multiple recycling instructional options (depending on application and regional infrastructure):

• Mechanical recycling

• Composting/biodegrading

• Renewable energy recovery incineration

•Anaerobic digestion

• Chemical recovery / raw material recovery

Low carbon footprint

Nowadays, the topic of environmental protection is getting more and more attention. PLA bioplastics offer a significantly reduced carbon footprint versus traditional oil-based plastics. That is important for the health of ourselves and the planet. Raw material classification

· High temperature PLA (CPLA): for demanding applications

· Standard PLA: for general purpose applications

· Low heat PLA: often used as a sealant

· PDLA: used as a nucleating agent or to make all-stereocomplexes.

What material is polylactic acid (PLA)?

Polylactic acid (PLA) is a bio-based and biodegradable polymer made from annually renewable resources.

Polylactic acid(PLA) is a thermoplastic aliphatic polyester. The lactic acid or lactide required for the production of polylactic acid(PLA) can be obtained by fermentation, dehydration and purification of renewable resources.

Polylactic acid generally has good mechanical properties and processing properties, and polylactic acid products can be quickly degraded in various ways after being discarded, and are truly pollution-free.

Polylactic acid(PLA) is a thermoplastic aliphatic polyester. The lactic acid or lactide required for the production of polylactic acid(PLA) can be obtained by fermentation, dehydration and purification of renewable resources.

Polylactic acid generally has good mechanical properties and processing properties, and polylactic acid products can be quickly degraded in various ways after being discarded, and are truly pollution-free.

What does bioplastic mean?

Environmental Protection

Bioplastics made from annually renewable biomass reduce our carbon footprint and reduce our reliance on fossil resources. They also offer a variety of scrapping options.

Positive economic benefits

Consumers are becoming more aware of their environmental benefits and are increasingly favoring greener plastics.

Bioplastics made from annually renewable biomass reduce our carbon footprint and reduce our reliance on fossil resources. They also offer a variety of scrapping options.

Positive economic benefits

Consumers are becoming more aware of their environmental benefits and are increasingly favoring greener plastics.

Why Choose Polylactic Acid (PLA)?

Bio-based PLA resin with multiple end-of-life options is made from renewable resources and is 100% bio-based according to EN16785-1. At the end of its useful life, polylactic acid (PLA) applications can be recycled mechanically or chemically. Polylactic acid (PLA) is also compostable according to EN13432. Compostable applications such as bin liners help divert valuable organic waste from landfills.

Efficient use of raw materials

PLA is a highly efficient plastic: it takes only 1.6 kg of sugar to make 1 kg of polylactic acid (PLA). Other types of bioplastics may require more natural resources to produce the same amount of final product.

Can be used on an industrial scale

PLA is commercially available on an industrial scale from several large factories around the world.

Proven Application

Commercial products made from PLA can already be found in a wide range of mature markets. Whether you are interested in molded parts, films, foams, 3D printing or fibers, you can turn to us for application development support.

PLA Products and Plastic Circular Economy

In a circular economy of PLA products, so-called "waste streams" and "end-of-life" products form the basis of new products, rather than being disposed of. This more holistic and sustainable approach replaces the linear economy with a circular bio-based economy in which products are produced from sustainable natural resources and reused and recycled wherever possible. At the end of their life cycle, these products have a range of options to convert them into new or value-added product life cycle feedstocks.

Multiple recycling instructional options (depending on application and regional infrastructure):

• Mechanical recycling

• Composting/biodegrading

• Renewable energy recovery incineration

•Anaerobic digestion

• Chemical recovery / raw material recovery

Low carbon footprint

Nowadays, the topic of environmental protection is getting more and more attention. PLA bioplastics offer a significantly reduced carbon footprint versus traditional oil-based plastics. That is important for the health of ourselves and the planet. Raw material classification

· High temperature PLA (CPLA): for demanding applications

· Standard PLA: for general purpose applications

· Low heat PLA: often used as a sealant

· PDLA: used as a nucleating agent or to make all-stereocomplexes.

Efficient use of raw materials

PLA is a highly efficient plastic: it takes only 1.6 kg of sugar to make 1 kg of polylactic acid (PLA). Other types of bioplastics may require more natural resources to produce the same amount of final product.

Can be used on an industrial scale

PLA is commercially available on an industrial scale from several large factories around the world.

Proven Application

Commercial products made from PLA can already be found in a wide range of mature markets. Whether you are interested in molded parts, films, foams, 3D printing or fibers, you can turn to us for application development support.

PLA Products and Plastic Circular Economy

In a circular economy of PLA products, so-called "waste streams" and "end-of-life" products form the basis of new products, rather than being disposed of. This more holistic and sustainable approach replaces the linear economy with a circular bio-based economy in which products are produced from sustainable natural resources and reused and recycled wherever possible. At the end of their life cycle, these products have a range of options to convert them into new or value-added product life cycle feedstocks.

Multiple recycling instructional options (depending on application and regional infrastructure):

• Mechanical recycling

• Composting/biodegrading

• Renewable energy recovery incineration

•Anaerobic digestion

• Chemical recovery / raw material recovery

Low carbon footprint

Nowadays, the topic of environmental protection is getting more and more attention. PLA bioplastics offer a significantly reduced carbon footprint versus traditional oil-based plastics. That is important for the health of ourselves and the planet. Raw material classification

· High temperature PLA (CPLA): for demanding applications

· Standard PLA: for general purpose applications

· Low heat PLA: often used as a sealant

· PDLA: used as a nucleating agent or to make all-stereocomplexes.

Get The Latest Price Or Free Sample,Contact With Us.

Whether you are looking for standard compounds or unique and challenging recipes - we are here for you! Please fill in the form and we will get back to you within 24 hours.

ADDRESS

ADDRESS11th Floor, Huasheng Building, Zhonglou District, Changzhou City, Jiangsu Province, China

PHONE NUMBER

PHONE NUMBER0086-15895068369

EMAIL

EMAIL

CopyRight © 2024 ChangZhou HuiSu QinYe Plastic Group All rights reserved

Sitemap

All tags

Designed by Zhonghuan Internet

PRODUCTS

PET SheetPVC Rigid SheetPVC Soft FilmPVC Foam BoardAcrylic SheetAPPLICATION

ThermoformingPrintFood PackagingPharmaceutical PackagingPHONE NUMBER: 0086-15895068369EMAIL: vivi@hgqyplastic.comAdd:11th floor,HUASHENG BUILDING ZhongLou District,ChangZhou City,JiangSu Province,China,213001ABOUT US

NEWSFAQDownloadSOCIAL MEDIA

LinkedinYoutubeTwitterFacebook

CopyRight © 2024 ChangZhou HuiSu QinYe Plastic Group

All rights reserved

Designed by

Zhonghuan Internet

Sitemap

All tags

vivi@hgqyplastic.com

vivi@hgqyplastic.com