Welcome To Visit Our Factory

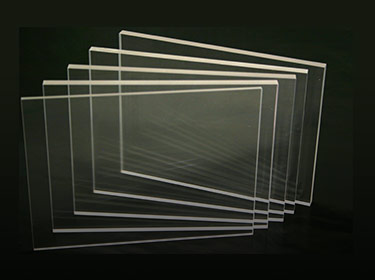

Huisu Qinye Plastic Group currently has more than 10 PETG sheet production lines with a daily output of 120 tons. We can use the best processing services to meet the procurement needs of different customers. PETG sheets can be produced in different thicknesses, widths and colors.

PRODUCTION STATUS

5-10 DAYS

<10tons

10-15 DAYS

10-20tons

15-20 DAYS

20-50tons

>20 DAYS

>50tons

HUISU QINYE PLASTIC has more than 20+ of plastic production lines, our monthly capacity is 5000tons,we supply PVC sheet, PET sheet/film, acrylic sheet and so on.

FAQ

- 1-5

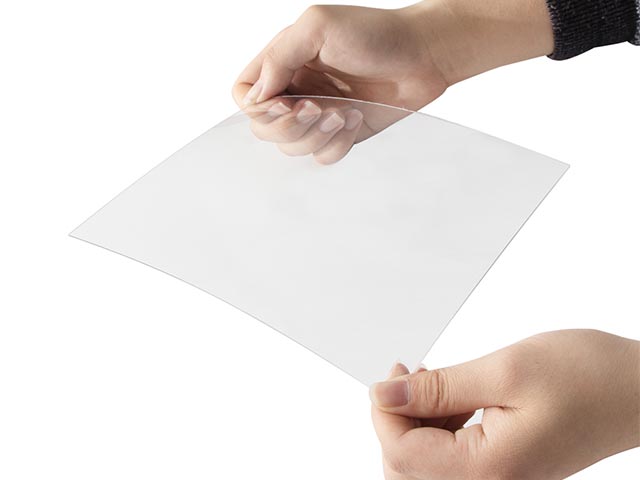

- What is PETG sheet?

- Polyethylene terephthalate, commonly referred to as PETG or PET-G, is a thermoplastic polyester with outstanding chemical resistance, durability, and excellent manufacturing formability. Due to the low forming temperature, PETG can be easily vacuum and pressure formed as well as heat-bent formed. This makes it very popular for consumer and commercial applications involving 3D printing or other thermoforming manufacturing techniques. Additionally, PETG is well suited for manufacturing techniques such as die cutting, routing and bending.

- What are the advantages of PETG SHEET?

- Compared to acrylic or polycarbonate, PETG is structurally strong and cost-effective. The unique properties of PETG sheet make it the first choice for impact-resistant glass and high-strength display scenarios. PETG sheets are suitable for digital printing and are suitable for product materials, displays and signage.

Generally speaking, PETG sheet is a food-safe plastic that is commonly used in food containers and liquid beverage bottles. Like acrylic and many other thermoplastics, PETG is fully recyclable. PETG is both thermoformable and vacuum formable, and can withstand tremendous pressure without cracking. It can be injection molded into various shapes or extruded into sheets.

The damage resistance of PETG is much higher than that of acrylic sheet and even rivals the impact resistance of polycarbonate. Also, PETG is easy to manufacture, making it the material of choice for professional manufacturers. - What are the applications of PETG sheet/film?

- PETG has good sheet processing performance, low material cost and extremely wide range of uses, such as vacuum forming, folding boxes, and printing.

Due to its ease of thermoforming and chemical resistance, PETG has a variety of uses. It is commonly used in single-use and reusable drinking bottles, edible oil containers, and FDA-compliant food storage containers. However, PETG packaging materials can also be used in the entire medical field. PETG's rigid structure allows it to withstand harsh sterilization processes, making it the perfect material for medical implants as well as pharmaceutical and medical device packaging.

PETG is an excellent material for 3D printing, and with its good processability and low material cost, it is quickly becoming a customer favorite. PETG screen printing easily has excellent layer adhesion and is odorless when printing. PETG also has very low shrink properties, allowing larger prints than materials such as PLA or ABS. At the same time, PETG sheets are very strong and have very good chemical resistance. This enables the PETG sheet to withstand high temperatures during printing, which is in line with food safety applications and applications in some special industries.

PETG plastic is often the material of choice for point-of-sale stands and other retail displays. Because PETG sheet is easy to manufacture in a variety of shapes and colors, businesses often use PETG material to create eye-catching signage that attracts customers. Additionally, PETG is easy to print, making custom complex images an affordable option. - What are the disadvantages of PETG sheet?

- Although PETG is naturally transparent, it can easily change color during processing. In addition, the biggest disadvantage of PETG Sheet is that the price is much more expensive than other materials such as PVC Sheet and APET Sheet.

- What is the most common thickness of PETG sheet?

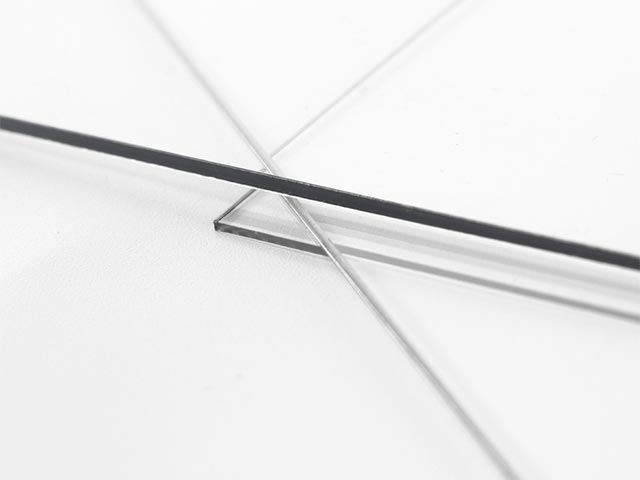

- It depends on your requirement, we can from 0.3 mm to 5 mm.

What is PETG sheet?

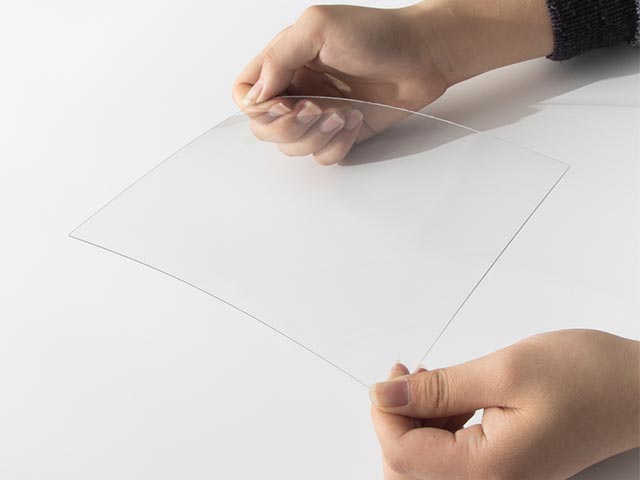

Polyethylene terephthalate, commonly referred to as PETG or PET-G, is a thermoplastic polyester with outstanding chemical resistance, durability, and excellent manufacturing formability. Due to the low forming temperature, PETG can be easily vacuum and pressure formed as well as heat-bent formed. This makes it very popular for consumer and commercial applications involving 3D printing or other thermoforming manufacturing techniques. Additionally, PETG is well suited for manufacturing techniques such as die cutting, routing and bending.

What are the advantages of PETG SHEET?

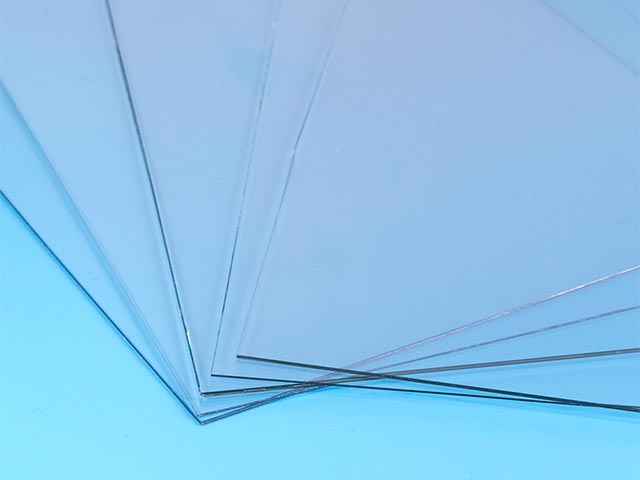

Compared to acrylic or polycarbonate, PETG is structurally strong and cost-effective. The unique properties of PETG sheet make it the first choice for impact-resistant glass and high-strength display scenarios. PETG sheets are suitable for digital printing and are suitable for product materials, displays and signage.

Generally speaking, PETG sheet is a food-safe plastic that is commonly used in food containers and liquid beverage bottles. Like acrylic and many other thermoplastics, PETG is fully recyclable. PETG is both thermoformable and vacuum formable, and can withstand tremendous pressure without cracking. It can be injection molded into various shapes or extruded into sheets.

The damage resistance of PETG is much higher than that of acrylic sheet and even rivals the impact resistance of polycarbonate. Also, PETG is easy to manufacture, making it the material of choice for professional manufacturers.

Generally speaking, PETG sheet is a food-safe plastic that is commonly used in food containers and liquid beverage bottles. Like acrylic and many other thermoplastics, PETG is fully recyclable. PETG is both thermoformable and vacuum formable, and can withstand tremendous pressure without cracking. It can be injection molded into various shapes or extruded into sheets.

The damage resistance of PETG is much higher than that of acrylic sheet and even rivals the impact resistance of polycarbonate. Also, PETG is easy to manufacture, making it the material of choice for professional manufacturers.

What are the applications of PETG sheet/film?

PETG has good sheet processing performance, low material cost and extremely wide range of uses, such as vacuum forming, folding boxes, and printing.

Due to its ease of thermoforming and chemical resistance, PETG has a variety of uses. It is commonly used in single-use and reusable drinking bottles, edible oil containers, and FDA-compliant food storage containers. However, PETG packaging materials can also be used in the entire medical field. PETG's rigid structure allows it to withstand harsh sterilization processes, making it the perfect material for medical implants as well as pharmaceutical and medical device packaging.

PETG is an excellent material for 3D printing, and with its good processability and low material cost, it is quickly becoming a customer favorite. PETG screen printing easily has excellent layer adhesion and is odorless when printing. PETG also has very low shrink properties, allowing larger prints than materials such as PLA or ABS. At the same time, PETG sheets are very strong and have very good chemical resistance. This enables the PETG sheet to withstand high temperatures during printing, which is in line with food safety applications and applications in some special industries.

PETG plastic is often the material of choice for point-of-sale stands and other retail displays. Because PETG sheet is easy to manufacture in a variety of shapes and colors, businesses often use PETG material to create eye-catching signage that attracts customers. Additionally, PETG is easy to print, making custom complex images an affordable option.

Due to its ease of thermoforming and chemical resistance, PETG has a variety of uses. It is commonly used in single-use and reusable drinking bottles, edible oil containers, and FDA-compliant food storage containers. However, PETG packaging materials can also be used in the entire medical field. PETG's rigid structure allows it to withstand harsh sterilization processes, making it the perfect material for medical implants as well as pharmaceutical and medical device packaging.

PETG is an excellent material for 3D printing, and with its good processability and low material cost, it is quickly becoming a customer favorite. PETG screen printing easily has excellent layer adhesion and is odorless when printing. PETG also has very low shrink properties, allowing larger prints than materials such as PLA or ABS. At the same time, PETG sheets are very strong and have very good chemical resistance. This enables the PETG sheet to withstand high temperatures during printing, which is in line with food safety applications and applications in some special industries.

PETG plastic is often the material of choice for point-of-sale stands and other retail displays. Because PETG sheet is easy to manufacture in a variety of shapes and colors, businesses often use PETG material to create eye-catching signage that attracts customers. Additionally, PETG is easy to print, making custom complex images an affordable option.

What are the disadvantages of PETG sheet?

Although PETG is naturally transparent, it can easily change color during processing. In addition, the biggest disadvantage of PETG Sheet is that the price is much more expensive than other materials such as PVC Sheet and APET Sheet.

What is the most common thickness of PETG sheet?

It depends on your requirement, we can from 0.3 mm to 5 mm.

Get The Latest Price Or Free Sample,Contact With Us.

Whether you are looking for standard compounds or unique and challenging recipes - we are here for you! Please fill in the form and we will get back to you within 24 hours.

ADDRESS

ADDRESS11th Floor, Huasheng Building, Zhonglou District, Changzhou City, Jiangsu Province, China

PHONE NUMBER

PHONE NUMBER0086-15895068369

EMAIL

EMAIL

CopyRight © 2024 ChangZhou HuiSu QinYe Plastic Group All rights reserved

Sitemap

All tags

Designed by Zhonghuan Internet

PRODUCTS

PET SheetPVC Rigid SheetPVC Soft FilmPVC Foam BoardAcrylic SheetAPPLICATION

ThermoformingPrintFood PackagingPharmaceutical PackagingPHONE NUMBER: 0086-15895068369EMAIL: vivi@hgqyplastic.comAdd:11th floor,HUASHENG BUILDING ZhongLou District,ChangZhou City,JiangSu Province,China,213001ABOUT US

NEWSFAQDownloadSOCIAL MEDIA

LinkedinYoutubeTwitterFacebook

CopyRight © 2024 ChangZhou HuiSu QinYe Plastic Group

All rights reserved

Designed by

Zhonghuan Internet

Sitemap

All tags

vivi@hgqyplastic.com

vivi@hgqyplastic.com