PRODUCTION STATUS

5-10 DAYS

<10tons

10-15 DAYS

10-20tons

15-20 DAYS

20-50tons

>20 DAYS

>50tons

HUISU QINYE PLASTIC has more than 20+ of plastic production lines, our monthly capacity is 5000tons,we supply PVC sheet, PET sheet/film, acrylic sheet and so on.

FAQ

- 1-6

- Alu Alu PVC Sheet – The Ultimate Guide

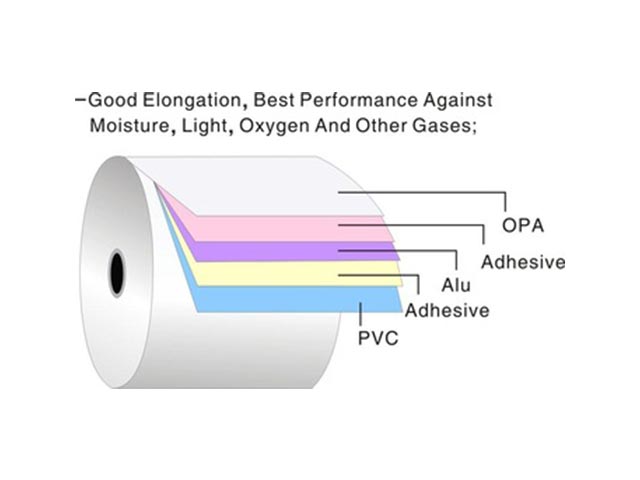

- Alu Alu Foil is an excellent multilayered structure designed for the high sensitive range of Pharmaceutical and generic medicines which are highly hygroscopic or light sensitive and cannot be suitably packed with barrier plastic films. The structure is an optimized combination of aluminum foil and polymeric films with the alumina layer sandwiched between an inner heat sealable polymeric film and outer supportive malleable film.

Cold-Formed BOPA film/Aluminum Foil/PVC film For Blister Packs are widely used in the blister packaging of pharmaceutical and food industries. It is sealed to aluminum blister foil, 600 times the barrier performance than PVC, 100 times the barrier than PVC/PVDC. - About Cold-Formed Alu Alu Foil

- Cold-formed aluminum foil is at the heart of alu alu OPA/Al/PVC sandwich foils used for pharmaceutical blister pack applications because of their inherently superior advantages. Aluminum, even in micron thickness, is the best vapor and light barrier besides providing the aesthetic shine for pharmaceutical blister packs.

- Key Benefits of alu-alu foil for blister packs

- 1. The most rigorous quality checks at all stages to ensure peace of mind and guaranteed risk-free use

2. Maximum protection and extended shelf life

3. Consistency, reliability, and affordability

4. High Malleability for deep drawing blister cavities

5. Sealable with normal Vmch based aluminum Foil

6. Effective anti-counterfeit packaging - Features of cold form alu-alu foil

- HSQY alu alu foils possess distinctive features that put them in a class apart:

1. 100% barrier to moisture, air, gases, light

2. Maximum fracture-free forming capabilities ensure “zero defect”

3. Superior process results in long term de-lamination resistance

4. Wide range of color and print options

5. Superior forming characteristics

6. Excellent thermal stability - What is 3 biggest Alu Alu PVC sheet manufacture in China?

- Jiangsu Jincai Polymer Materials Science And Technology Co., Ltd.

Changzhou Huisu Qinye Plastic Group

Jiangsu Jiujiu Material Technology Co., Ltd. - What is the most common thickness of Alu Alu PVC sheet?

- Mostly it is 60 micron and 70 micron, while other thickness can also be customized.

Alu Alu PVC Sheet – The Ultimate Guide

Alu Alu Foil is an excellent multilayered structure designed for the high sensitive range of Pharmaceutical and generic medicines which are highly hygroscopic or light sensitive and cannot be suitably packed with barrier plastic films. The structure is an optimized combination of aluminum foil and polymeric films with the alumina layer sandwiched between an inner heat sealable polymeric film and outer supportive malleable film.

Cold-Formed BOPA film/Aluminum Foil/PVC film For Blister Packs are widely used in the blister packaging of pharmaceutical and food industries. It is sealed to aluminum blister foil, 600 times the barrier performance than PVC, 100 times the barrier than PVC/PVDC.

Cold-Formed BOPA film/Aluminum Foil/PVC film For Blister Packs are widely used in the blister packaging of pharmaceutical and food industries. It is sealed to aluminum blister foil, 600 times the barrier performance than PVC, 100 times the barrier than PVC/PVDC.

About Cold-Formed Alu Alu Foil

Cold-formed aluminum foil is at the heart of alu alu OPA/Al/PVC sandwich foils used for pharmaceutical blister pack applications because of their inherently superior advantages. Aluminum, even in micron thickness, is the best vapor and light barrier besides providing the aesthetic shine for pharmaceutical blister packs.

Key Benefits of alu-alu foil for blister packs

1. The most rigorous quality checks at all stages to ensure peace of mind and guaranteed risk-free use

2. Maximum protection and extended shelf life

3. Consistency, reliability, and affordability

4. High Malleability for deep drawing blister cavities

5. Sealable with normal Vmch based aluminum Foil

6. Effective anti-counterfeit packaging

2. Maximum protection and extended shelf life

3. Consistency, reliability, and affordability

4. High Malleability for deep drawing blister cavities

5. Sealable with normal Vmch based aluminum Foil

6. Effective anti-counterfeit packaging

Features of cold form alu-alu foil

HSQY alu alu foils possess distinctive features that put them in a class apart:

1. 100% barrier to moisture, air, gases, light

2. Maximum fracture-free forming capabilities ensure “zero defect”

3. Superior process results in long term de-lamination resistance

4. Wide range of color and print options

5. Superior forming characteristics

6. Excellent thermal stability

1. 100% barrier to moisture, air, gases, light

2. Maximum fracture-free forming capabilities ensure “zero defect”

3. Superior process results in long term de-lamination resistance

4. Wide range of color and print options

5. Superior forming characteristics

6. Excellent thermal stability

What is 3 biggest Alu Alu PVC sheet manufacture in China?

Jiangsu Jincai Polymer Materials Science And Technology Co., Ltd.

Changzhou Huisu Qinye Plastic Group

Jiangsu Jiujiu Material Technology Co., Ltd.

Changzhou Huisu Qinye Plastic Group

Jiangsu Jiujiu Material Technology Co., Ltd.

What is the most common thickness of Alu Alu PVC sheet?

Mostly it is 60 micron and 70 micron, while other thickness can also be customized.

Get The Latest Price Or Free Sample,Contact With Us.

Whether you are looking for standard compounds or unique and challenging recipes - we are here for you! Please fill in the form and we will get back to you within 24 hours.

ADDRESS

ADDRESS11th Floor, Huasheng Building, Zhonglou District, Changzhou City, Jiangsu Province, China

PHONE NUMBER

PHONE NUMBER0086-15895068369

EMAIL

EMAIL

CopyRight © 2024 ChangZhou HuiSu QinYe Plastic Group All rights reserved

Sitemap

All tags

Designed by Zhonghuan Internet

PRODUCTS

PET SheetPVC Rigid SheetPVC Soft FilmPVC Foam BoardAcrylic SheetAPPLICATION

ThermoformingPrintFood PackagingPharmaceutical PackagingPHONE NUMBER: 0086-15895068369EMAIL: vivi@hgqyplastic.comAdd:11th floor,HUASHENG BUILDING ZhongLou District,ChangZhou City,JiangSu Province,China,213001ABOUT US

NEWSFAQDownloadSOCIAL MEDIA

LinkedinYoutubeTwitterFacebook

CopyRight © 2024 ChangZhou HuiSu QinYe Plastic Group

All rights reserved

Designed by

Zhonghuan Internet

Sitemap

All tags

vivi@hgqyplastic.com

vivi@hgqyplastic.com