Welcome To Visit Our Factory

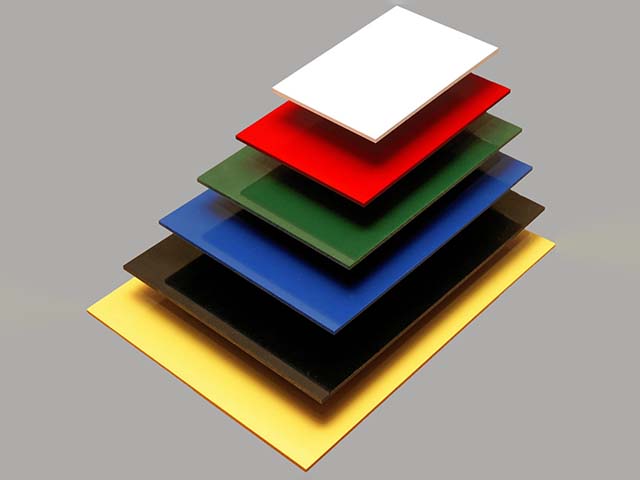

Huisu Qinye Plastic Group has more than 6 polystyrene sheet production lines with a daily output of 120 tons. We produce polystyrene in many varieties such as glossy polystyrene, matt polystyrene, clear polystyrene, opaque polystyrene, thick polystyrene sheet, thin polystyrene sheet, polystyrene coil, High impact polystyrene, insulating polystyrene, expanded polystyrene, extruded polystyrene, etc. We pay equal attention to the concept of quality and service, and the performance has won the trust of customers.

PRODUCTION STATUS

5-10 DAYS

<10tons

10-15 DAYS

10-20tons

15-20 DAYS

20-50tons

>20 DAYS

>50tons

HUISU QINYE PLASTIC has more than 20+ of plastic production lines, our monthly capacity is 5000tons,we supply PVC sheet, PET sheet/film, acrylic sheet and so on.

FAQ

- 1-5

- What is polystyrene sheet?

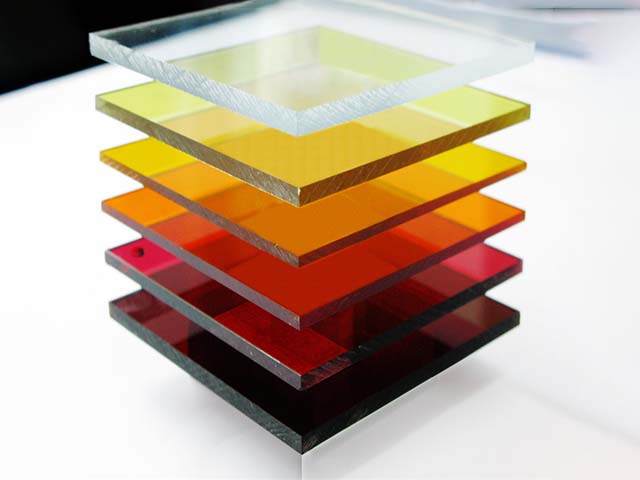

- Polystyrene sheet, also known as PS sheet, can be divided into GPPS sheet and HIPS sheet. GPPS is mainly used in bathroom, decoration, isolation, diffuser panel applications, etc. GPPS is mainly used for thermoforming, advertising, printing. HIPS sheet mainly includes fountain HIPS board, black HIPS plastic sheet, extruded HIPS plastic sheet, HIPS thermoforming plastic sheet, matt HIPS plastic sheet for advertising digital printing, refrigerator HIPS plastic sheet, refrigerator lining HIPS sheet etc.

Polystyrene rigid sheets also offer high strength and excellent stability, are non-flammable, and resist corrosion caused by climate change. Common polystyrene sheets include glossy polystyrene sheet, transparent polystyrene sheet, matt polystyrene sheet, white polystyrene sheet, black polystyrene sheet, gray polystyrene sheet, color polystyrene sheet, polystyrene sheet, etc. - What are the advantages of polystyrene sheet?

- 1. The density coefficient of polystyrene foam board is small, and the impact resistance is good. By changing and restoring the shape, it has enough ability to buffer external impact.

2. Independent bubble structure, small area damage will not affect the whole wall;

3. The surface water absorption rate is low and the impermeability is good, which can effectively avoid the problems of mold and falling off after the wall is damp;

4. Polystyrene has low melt viscosity, good fluidity and wide melting temperature range. At high temperature, styrofoam will not melt due to high temperature, nor will it crack at low temperature due to low temperature.

5. Styrofoam is a recyclable and recyclable material, and the highest recycling rate is plastic.

6. Freon is not used in the production process;

7. The energy consumption of the whole life cycle is the lowest among plastic products. - What are the applications of polystyrene sheet/polystyrene sheet?

- GPPS is mainly used in bathroom, decoration, isolation, diffuser panel applications, etc. HIPS is mainly used for thermoforming, advertising, printing, etc.

Polystyrene sheets are widely used, and there are many types of polystyrene sheets. Therefore, polystyrene can be used for injection molding, extrusion, blow molding, and foam thermoforming, as well as welding and machining. Molded products mainly include daily necessities, films, sheets, hollow containers, parts of instruments and equipment, etc. Polystyrene resin is widely used in injection molding plastic products. Injection molding of transparent and colorful daily necessities such as pots, plates, lamps, student stationery, and various home decorations; industrial accessories, such as watch cases, lamps, optical parts, electrical appliances, communication parts, etc.

Because of its good workability, low manufacturing cost, corrosion resistance and insulation. Polystyrene materials are widely used, mainly used for making advertising printing. - What are the disadvantages of polystyrene sheet?

- 1. The construction requires net hanging, the construction process is cumbersome and the construction period is long;

2. It produces flammable and toxic gas after burning. Ordinary polystyrene foam insulation board is easy to burn, and the smoke produced by burning is toxic. Even with the addition of flame retardants, the flammability is only Class B.

3. The material strength is poor, easy to crack, and the insulating layer falls off;

4. Due to its limited strength and poor bearing capacity, polystyrene foam insulation board needs to be strengthened when facing bricks.

5. The quality of the polystyrene foam insulation board is unstable, because the material needs to be placed for a period of time before leaving the factory. After a period of maturity, it can be used. If it is not fully cured, the quality will not be guaranteed, causing the foam board to shrink and crack. - What is the most common thickness of Polystyrene sheet?

- This depends on your requirement, we can make it from 0.5mm to 10mm.

What is polystyrene sheet?

Polystyrene sheet, also known as PS sheet, can be divided into GPPS sheet and HIPS sheet. GPPS is mainly used in bathroom, decoration, isolation, diffuser panel applications, etc. GPPS is mainly used for thermoforming, advertising, printing. HIPS sheet mainly includes fountain HIPS board, black HIPS plastic sheet, extruded HIPS plastic sheet, HIPS thermoforming plastic sheet, matt HIPS plastic sheet for advertising digital printing, refrigerator HIPS plastic sheet, refrigerator lining HIPS sheet etc.

Polystyrene rigid sheets also offer high strength and excellent stability, are non-flammable, and resist corrosion caused by climate change. Common polystyrene sheets include glossy polystyrene sheet, transparent polystyrene sheet, matt polystyrene sheet, white polystyrene sheet, black polystyrene sheet, gray polystyrene sheet, color polystyrene sheet, polystyrene sheet, etc.

Polystyrene rigid sheets also offer high strength and excellent stability, are non-flammable, and resist corrosion caused by climate change. Common polystyrene sheets include glossy polystyrene sheet, transparent polystyrene sheet, matt polystyrene sheet, white polystyrene sheet, black polystyrene sheet, gray polystyrene sheet, color polystyrene sheet, polystyrene sheet, etc.

What are the advantages of polystyrene sheet?

1. The density coefficient of polystyrene foam board is small, and the impact resistance is good. By changing and restoring the shape, it has enough ability to buffer external impact.

2. Independent bubble structure, small area damage will not affect the whole wall;

3. The surface water absorption rate is low and the impermeability is good, which can effectively avoid the problems of mold and falling off after the wall is damp;

4. Polystyrene has low melt viscosity, good fluidity and wide melting temperature range. At high temperature, styrofoam will not melt due to high temperature, nor will it crack at low temperature due to low temperature.

5. Styrofoam is a recyclable and recyclable material, and the highest recycling rate is plastic.

6. Freon is not used in the production process;

7. The energy consumption of the whole life cycle is the lowest among plastic products.

2. Independent bubble structure, small area damage will not affect the whole wall;

3. The surface water absorption rate is low and the impermeability is good, which can effectively avoid the problems of mold and falling off after the wall is damp;

4. Polystyrene has low melt viscosity, good fluidity and wide melting temperature range. At high temperature, styrofoam will not melt due to high temperature, nor will it crack at low temperature due to low temperature.

5. Styrofoam is a recyclable and recyclable material, and the highest recycling rate is plastic.

6. Freon is not used in the production process;

7. The energy consumption of the whole life cycle is the lowest among plastic products.

What are the applications of polystyrene sheet/polystyrene sheet?

GPPS is mainly used in bathroom, decoration, isolation, diffuser panel applications, etc. HIPS is mainly used for thermoforming, advertising, printing, etc.

Polystyrene sheets are widely used, and there are many types of polystyrene sheets. Therefore, polystyrene can be used for injection molding, extrusion, blow molding, and foam thermoforming, as well as welding and machining. Molded products mainly include daily necessities, films, sheets, hollow containers, parts of instruments and equipment, etc. Polystyrene resin is widely used in injection molding plastic products. Injection molding of transparent and colorful daily necessities such as pots, plates, lamps, student stationery, and various home decorations; industrial accessories, such as watch cases, lamps, optical parts, electrical appliances, communication parts, etc.

Because of its good workability, low manufacturing cost, corrosion resistance and insulation. Polystyrene materials are widely used, mainly used for making advertising printing.

Polystyrene sheets are widely used, and there are many types of polystyrene sheets. Therefore, polystyrene can be used for injection molding, extrusion, blow molding, and foam thermoforming, as well as welding and machining. Molded products mainly include daily necessities, films, sheets, hollow containers, parts of instruments and equipment, etc. Polystyrene resin is widely used in injection molding plastic products. Injection molding of transparent and colorful daily necessities such as pots, plates, lamps, student stationery, and various home decorations; industrial accessories, such as watch cases, lamps, optical parts, electrical appliances, communication parts, etc.

Because of its good workability, low manufacturing cost, corrosion resistance and insulation. Polystyrene materials are widely used, mainly used for making advertising printing.

What are the disadvantages of polystyrene sheet?

1. The construction requires net hanging, the construction process is cumbersome and the construction period is long;

2. It produces flammable and toxic gas after burning. Ordinary polystyrene foam insulation board is easy to burn, and the smoke produced by burning is toxic. Even with the addition of flame retardants, the flammability is only Class B.

3. The material strength is poor, easy to crack, and the insulating layer falls off;

4. Due to its limited strength and poor bearing capacity, polystyrene foam insulation board needs to be strengthened when facing bricks.

5. The quality of the polystyrene foam insulation board is unstable, because the material needs to be placed for a period of time before leaving the factory. After a period of maturity, it can be used. If it is not fully cured, the quality will not be guaranteed, causing the foam board to shrink and crack.

2. It produces flammable and toxic gas after burning. Ordinary polystyrene foam insulation board is easy to burn, and the smoke produced by burning is toxic. Even with the addition of flame retardants, the flammability is only Class B.

3. The material strength is poor, easy to crack, and the insulating layer falls off;

4. Due to its limited strength and poor bearing capacity, polystyrene foam insulation board needs to be strengthened when facing bricks.

5. The quality of the polystyrene foam insulation board is unstable, because the material needs to be placed for a period of time before leaving the factory. After a period of maturity, it can be used. If it is not fully cured, the quality will not be guaranteed, causing the foam board to shrink and crack.

What is the most common thickness of Polystyrene sheet?

This depends on your requirement, we can make it from 0.5mm to 10mm.

Get The Latest Price Or Free Sample,Contact With Us.

Whether you are looking for standard compounds or unique and challenging recipes - we are here for you! Please fill in the form and we will get back to you within 24 hours.

ADDRESS

ADDRESS11th Floor, Huasheng Building, Zhonglou District, Changzhou City, Jiangsu Province, China

PHONE NUMBER

PHONE NUMBER0086-15895068369

EMAIL

EMAIL

CopyRight © 2024 ChangZhou HuiSu QinYe Plastic Group All rights reserved

Sitemap

All tags

Designed by Zhonghuan Internet

PRODUCTS

PET SheetPVC Rigid SheetPVC Soft FilmPVC Foam BoardAcrylic SheetAPPLICATION

ThermoformingPrintFood PackagingPharmaceutical PackagingPHONE NUMBER: 0086-15895068369EMAIL: vivi@hgqyplastic.comAdd:11th floor,HUASHENG BUILDING ZhongLou District,ChangZhou City,JiangSu Province,China,213001ABOUT US

NEWSFAQDownloadSOCIAL MEDIA

LinkedinYoutubeTwitterFacebook

CopyRight © 2024 ChangZhou HuiSu QinYe Plastic Group

All rights reserved

Designed by

Zhonghuan Internet

Sitemap

All tags

vivi@hgqyplastic.com

vivi@hgqyplastic.com